The rigid method of design of combined footings assumes that

1. The footing or mat is infinitely rigid, and therefore, the deflection of the footing or mat does not influence the pressure distribution,

2. The soil pressure is distributed in a straight line or a plane surface such that the centroid of the soil pressure coincides with the line of action of the resultant force of all the loads acting on the foundation.

Design of Combined Footings

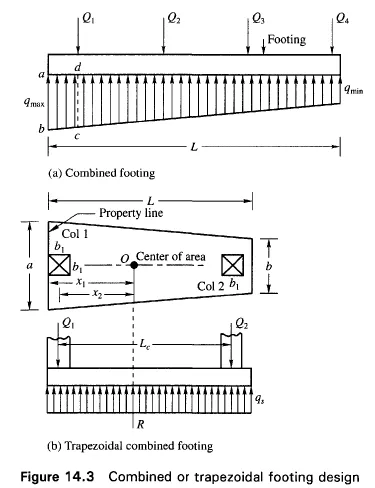

Two or more columns in a row joined together by a stiff continuous footing form a combined footing as shown in Fig. 14.3a. The procedure of design for a combined footing is as follows:

1. Determine the total column loads Qtotal = Q1 +Q2 + Q3+ … and location of the line of action of the resultant TotalQ. If any column is subjected to bending moment, the effect of the moment should be taken into account.

2. Determine the pressure distribution q per lineal length of footing.

3. Determine the width, B, of the footing.

4. Draw the shear diagram along the length of the footing. By definition, the shear at any section along the beam is equal to the summation of all vertical forces to the left or right of the section. For example, the shear at a section immediately to the left of Q1 is equal to the area abed, and immediately to the right of Q1 is equal to (abcd – Q1) as shown in Fig. 14.3a.

5. Draw the moment diagram along the length of the footing. By definition the bending moment at any section is equal to the summation of moment due to all the forces and reaction to the left (or right) of the section. It is also equal to the area under the shear diagram to the left (or right) of the section.

6. Design the footing as a continuous beam to resist the shear and moment.

7. Design the footing for transverse bending in the same manner as for spread footings.

It should be noted here that the end column along the property line may be connected to the interior column by a rectangular or trapezoidal footing. In such a case no strap is required and both the columns together will be a combined footing as shown in Fig. 14.3b. It is necessary that the center of area of the footing must coincide with the center of loading for the pressure to remain uniform.