Bearing capacities of rocks are often determined by crushing a core sample in a testing machine. Samples used for testing must be free from cracks and defects.

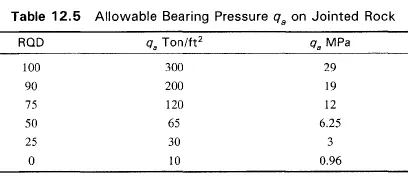

In the rock formation where bedding planes, joints and other planes of weakness exist, the practice that is normally followed is to classify the rock according to RQD (Rock Quality Designation). Table 9.2 gives the classification of the bearing capacity of rock according to RQD. Peck et al, (1974) have related the RQD to the allowable bearing pressure qa as given in Table 12.5

The RQD for use in Table 12.5 should be the average within a depth below foundation level equal to the width of the foundation, provided the RQD is fairly uniform within that depth. If the upper part of the rock, within a depth of about 5/4, is of lower quality, the value of this part should be used.

Another practice that is normally followed is to base the allowable pressure on the unconfined compressive strength, qu, of the rock obtained in a laboratory on a rock sample. A factor of safety of 5 to 8 is used on qu to obtain qa. Past experience indicates that this method is satisfactory so long as the rocks in situ do not possess extensive cracks and joints. In such cases a higher factor of safety may have to be adopted.

If rocks close to a foundation base are highly fissured/fractured, they can be treated by grouting which increases the bearing capacity of the material.

The bearing capacity of a homogeneous, and discontinuous rock mass cannot be less than the unconfined compressive strength of the rock mass around the footing and this can be taken as a lower bound for a rock mass with constant angle of internal friction 0 and unconfined compressive strength qur. Goodman (1980) suggests the following equation for determining the ultimate bearing capacity qu.

![]()

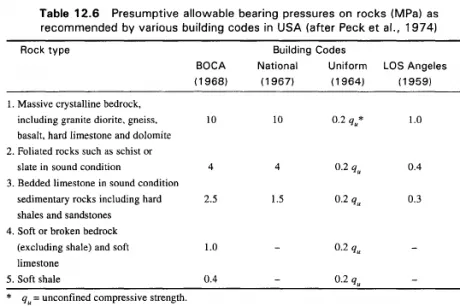

Recommendations by Building Codes

Where bedrock can be reached by excavation, the presumptive allowable bearing pressure is specified by Building Codes. Table 12.7 gives the recommendations of some buildings codes in the U.S.