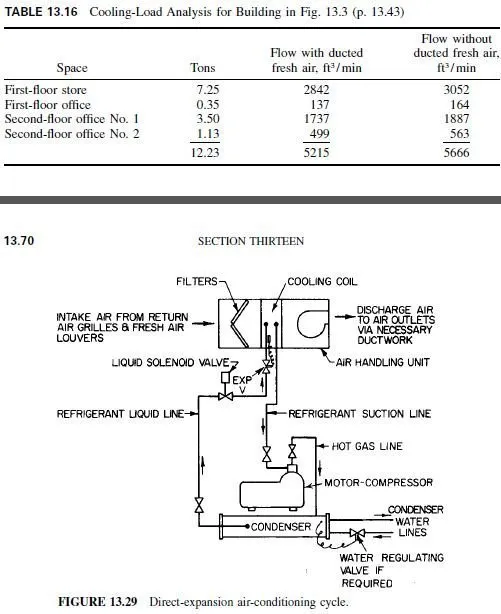

Figure 13.29 shows the basic air-conditioning cycle of the direct-expansion type.

The compressor takes refrigerant gas at a relatively low pressure and compresses it to a higher pressure. The hot gas is passed to a condenser where heat is removed and the refrigerant liquefied. The liquid is then piped to the cooling coil of the airhandling unit and allowed to expand to a lower pressure (suction pressure). The liquid vaporizes or is boiled off by the relatively warm air passing over the coil.

The compressor pulls away the vaporized refrigerant to maintain the required low coil pressure with its accompanying low temperature.

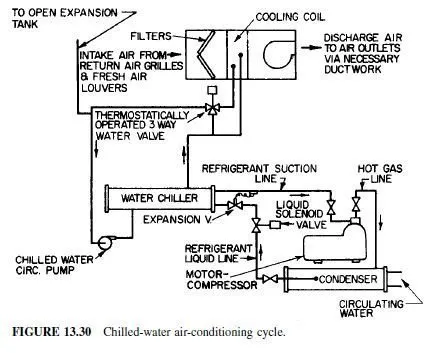

Chilled-Water Refrigeration Cycle. In some systems, water is chilled by the refrigerant and circulated to units in or near spaces to be cooled (Fig. 13.30), where air is cooled by the water.

In water-cooled and belt-driven air-conditioning compressors formerly used, motor winding heat was usually dissipated into the atmosphere outside the conditioned space (usually into the compressor rooms). For average air-conditioning service 1 hp could produce about 1 ton of cooling. When sealed compressor-motor units came into use, the motor windings were arranged to give off their heat to the refrigerant suction gas. This heat was therefore added to the cooling load of the compressor. The result was that 1 hp could produce only about 0.85 ton of cooling.

Because of water shortages, many communities restrict the direct use of city water for condensing purposes. As an alternative, water can be cooled with cooling towers and recirculated. But for smaller systems, cooling towers have some inherent disadvantages. As a result, air-cooled condensers have become common for smalland medium-sized air-conditioning systems. Because of the higher head pressures resulting from air-cooled condensers, each horsepower of compressor-motor will produce only about 0.65 ton of cooling. Because of these developments, airconditioning equipment manufacturers rate their equipment in Btu per hour output and kilowatts required for the rated output, at conditions standardized by the industry, instead of in horsepower.