For general purposes, A325 and A490 high-strength bolts may be specified. Each type of bolt can be identified by the ASTM designation and the manufacturers mark on the bolt head and nut (Fig. 5.1). The cost of A490 bolts is 15 to 20% greater than that of A325 bolts.

Job specifications often require that main connections shall be made with bolts conforming to the Specification for Structural Joints Using ASTM A325 and A490 Bolts. This

specification, approved by the Research Council on Structural Connections (RCSC) of the Engineering Foundation, establishes bolt, nut, and washer dimensions, minimum fastener tension, and requirements for design and installation.

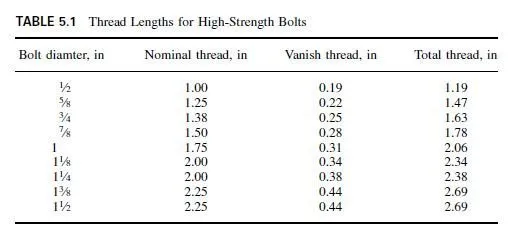

As indicated in Table 5.1, many sizes of high-strength bolts are available. Most standard connection tables, however, apply primarily to 3â„4-and 7â„8-in bolts. Shop and erection equipment is generally set up for these sizes, and workers are familiar with them.

Bearing versus Slip-Critical Joints. Connections made with high-strength bolts may be slip-critical (material joined being clamped together by the tension induced in the bolts by tightening them) or bearing-type (material joined being restricted from moving primarily by the bolt shank). In bearing-type connections, bolt threads may be included in or excluded from the shear plane. Different stresses are allowed for each condition. The slip-critical connection is the most expensive, because it requires that the faying surfaces be free of paint (some exceptions are permitted), grease, and oil. Hence this type of connection should be used only where required by the governing design specification, e.g., where it is undesirable to have the bolts slip into bearing or where stress reversal could cause slippage (Art. 5.1).

Slip-critical connections, however, have the advantage in building construction that when

used in combination with welds, the fasteners and welds may be considered to share the

stress (Art. 5.2). Another advantage that sometimes may be useful is that the strength of

slip-critical connections is not affected by bearing limitations, as are other types of fasteners.

Threads in Shear Planes. The bearing-type connection with threads in shear planes is frequently used. Since location of threads is not restricted, bolts can be inserted from either side of a connection. Either the head or the nut can be the element turned. Paint is permitted on the faying surfaces.

Threads Excluded from Shear Planes. The bearing-type connection with threads excluded from shear planes is the most economical high-strength bolted connection, because fewer bolts generally are needed for a given capacity. But this type should be used only after careful consideration of the difficulties involved in excluding the threads from the shear planes. The location of the thread runout depends on which side of the connection the bolt is entered and whether a washer is placed under the head or the nut. This location is difficult to control in the shop but even more so in the field. The difficulty is increased by the fact that much of the published information on bolt characteristics does not agree with the basic specification used by bolt manufacturers (American National Standards Institute B18.2.1).

Thread Length and Bolt Length. Total nominal thread lengths and vanish thread lengths for high-strength bolts are given in Table 5.1. It is common practice to allow the last 1â„8 in of vanish thread to extend across a single shear plane. In order to determine the required bolt length, the value shown in Table 5.2 should be added to the grip (i.e., the total thickness

of all connected material, exclusive of washers). For each hardened flat washer that is used, add 5â„32 in, and for each beveled washer, add 5â„16 in. The tabulated values provide appropriate allowances for manufacturing tolerances and also provide for full thread engagement with an installed heavy hex nut. The length determined by the use of Table 5.2 should be adjusted to the next longer 1â„4-in length.

Washer Requirements. The RCSC specification requires that design details provide for washers in connections with high-strength bolts as follows:

1. A hardened beveled washer should be used to compensate for the lack of parallelism where the outer face of the bolted parts has a greater slope than 1:20 with respect to a plane normal to the bolt axis.

2. For A325 and A490 bolts for slip-critical connections and connections subject to direct tension, hardened washers are required as specified in items 3 through 7 below. For bolts permitted to be tightened only snug-tight, if a slotted hole occurs in an outer ply, a flat hardened washer or common plate washer shall be installed over the slot. For other connections with A325 and A490 bolts, hardened washers are not generally required.

3. When the calibrated wrench method is used for tightening the bolts, hardened washers shall be used under the element turned by the wrench.

4. For A490 bolts tensioned to the specified tension, hardened washers shall be used under the head and nut in steel with a specified yield point less than 40 ksi.

5. A hardened washer conforming to ASTM F436 shall be used for A325 or A490 bolts 1 in or less in diameter tightened in an oversized or short slotted hole in an outer ply.

6. Hardened washers conforming to F436 but at least 5â„16 in thick shall be used, instead of washers of standard thickness, under both the head and nut of A490 bolts more than 1 in in diameter tightened in oversized or short slotted holes in an outer ply. This requirement is not met by multiple washers even though the combined thickness equals or exceeds 5â„16 in.

7. A plate washer or continuous bar of structural-grade steel, but not necessarily hardened, at least 5â„16 in thick and with standard holes, shall be used for an A325 or A490 bolt 1 in or less in diameter when it is tightened in a long slotted hole in an outer ply. The washer or bar shall be large enough to cover the slot completely after installation of the tightened bolt. For an A490 bolt more than 1 in in diameter in a long slotted hole in an outer ply, a single hardened washer (not multiple washers) conforming to F436, but at least 5â„16 in thick, shall be used instead of a washer or bar of structural-grade steel.

The requirements for washers specified in items 4 and 5 above are satisfied by other types of fasteners meeting the requirements of A325 or A490 and with a geometry that provides a bearing circle on the head or nut with a diameter at least equal to that of hardened F436 washers. Such fasteners include twist-off bolts with a splined end that extends beyond the threaded portion of the bolt. During installation, this end is gripped by a special wrench chuck and is sheared off when the specified bolt tension is achieved.

The RCSC specification permits direct tension-indicating devices, such as washers incorporating small, formed arches designed to deform in a controlled manner when subjected to the tightening force. The specification also provides guidance on use of such devices to assure proper installation (Art. 5.14).