Traditionally, enhanced durability of concrete is associated with reducing the water/cement ratio. This has some benefit in the case of freezing and thawing by reducing the free water content, which reduces the amount of water available for ice formation. However, the improved microstructure, consequent on lowering the water/cement ratio, may restrict the movement of water and cause stress build-up. Air entrainment provides a controlled method of accommodating the water movement caused during ice formation. Entrained air bubbles protect the surrounding spheres of concrete (Powers, 1949).

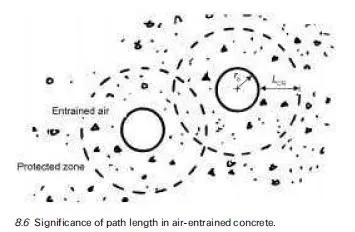

The concept of protection is illustrated in Fig. 8.6. During the freezing phase water has space to move without causing undue pressure and, on thawing, the water in the entrained voids is drawn back out into the narrower pore network by capillary forces. Controlled entrainment of air is achieved by adding an admixture to the concrete that is capable of distributing discrete air bubbles.

Enhanced freeze-thaw durability by air entrainment involves provision of a sufficient content of entrained air for a given threat combined with a satisfactory distribution of air bubbles. This not only provides millions of safety valves per cubic metre of concrete but, as a beneficial side effect, it may also enhance the surface layers of slabs and pavements. Air entraining admixtures increase the workability and cohesiveness of mixes. This reduces bleed water and laitance thus making surface layers more robust and less likely to fail.