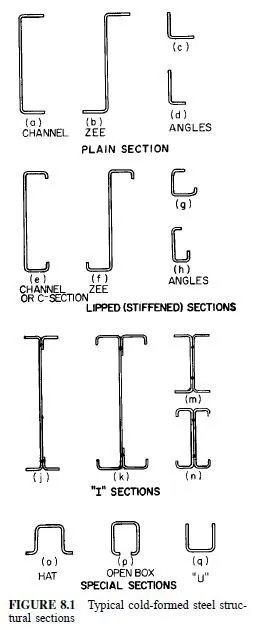

Many cold-formed shapes used for structural purposes are similar in their general configurations to hot-rolled structural sections. Channels, angles, and zees can be roll-formed in a single operation from one piece of material. I sections are usually made by welding two channels back to back or by welding two angles to a channel.

All sections of this kind may be made with either plain flanges as in Fig. 8.1a to d, j, and m or with flanges stiffened by means of lips at outer edges, as in Fig. 8.1e to h, k, and n.

In addition to these sections, which follow somewhat conventional lines and have their counterparts in hot-rolled structural sections, the flexibility of the forming process makes it relatively easy to obtain inverted U, or hat-shaped, sections and open box sections (Fig. 8.1o to q). These sections are very stiff in a lateral direction and can be used without lateral support where other more conventional types of sections would fail because of lateral instability.

Other special shapes are illustrated in Fig. 8.2. Some of these are nonstructural in nature; others are used for specialpurpose structural members. Figure 8.3 shows a few cold-formed stainless steel sections.

An important characteristic of coldformed shapes is that the thickness of section is substantially uniform. (A slight reduction in thickness may occur at bends, but that may be ignored for computing weights and section properties.)

This means that, for a specified thickness, the amount of flange material in a section, such as a channel, is almost entirely a function of the width of the section, except for shapes where additional flange area is obtained by doubling the material back on itself.

Another distinguishing feature of cold-formed sections is that the corners are rounded on both the inside and the outside of the bend, since the shapes are formed by bending flat material.

Sharp corners, such as can be obtained with hot-rolled structural channels, angles, and zees, cannot be obtained in cold-formed shapes by simple bending, although they can be achieved in a coining or upsetting operation. This, however, is not customary in the manufacture of structural cold-formed sections;

and in proportioning such sections, the inside radius of bends should never be less, and should preferably be 33 to 100% greater, than specified for the relatively narrow ASTM bend-test specimens. Deck and panel sections, such as are used for floors, roofs, and walls, are as a rule considerably wider, relative to their depth, than are the structural framing members shown in Figs. 8.1 to 8.3.

DESIGN PRINCIPLES FOR COLD-FORMED STEEL SHAPES

The structural behavior of cold-formed shapes follows the same laws of structural mechanics as does that of conventional structural-steel shapes and plates. Thus, design procedures commonly used in the selection of hot-rolled shapes are generally applicable to cold-formed sections. Although only a portion of a section, in some cases, may be considered structurally effective, computation of the structural properties of the effective option follows conventional procedure.