Structural clay tiles are hollow burned-clay masonry units with parallel cells. Such units have multitude of uses: as a facing tile for interior and exterior unplastered walls, partitions, or columns; as load-bearing tile in masonry constructions designed to carry superimposed loads; as partition tile for interior partitions carrying no superimposed load; as fireproofing tile for protection of structural members against fire; as furring tile for lining the inside of exterior walls; as floor tile in floor and roof construction; and as header tiles, which are designed to provide recesses for header units in brick or stone-faced walls. Units are available with the following ranges in nominal dimensions: 8 to 16 in in length, 4 in for facing tile to 12 in for load-bearing tile in height, and 2 in for facing tile to 12 in for load-bearing tile in thickness.

Two general types of tile are available side-construction tile, designed to receive its principal stress at right angles to the axis of the cells, and end-construction tile designed to receive its principal stress parallel to the axis of the cells.

Tiles are also available in a number of surface finishes, such as opaque glazed tile, clear ceramic-glazed tile, nonlustrous glazed tile, and scored, combed, or roughened finishes designed to receive mortar, plaster, or stucco.

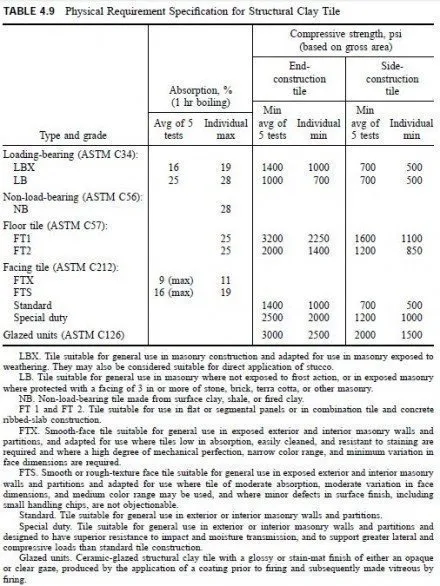

Requirements of the appropriate ASTM specifications for absorption and strength of several types of tile are given in Table 4.9 (see ASTM C34, C56, C57, C212, and C126 for details pertaining to size, color, texture, defects, etc.). Strength and absorption of tile made from similar clays but from different sources and manufacturers vary widely. The modulus of elasticity of tile may range from 1,620,000 to 6,059,000 psi.