Several types of joints may occur or be formed in concrete structures:

Construction joints are formed when fresh concrete is placed against hardened concrete.

Expansion joints are provided in long components to relieve compressive stresses that would otherwise result from a temperature rise.

Contraction joints (control joints) are provided to permit concrete to contract during a drop in temperature and to permit drying shrinkage without resulting uncontrolled random cracking.

Contraction joints should be located at places where concrete is likely to crack because of temperature changes or shrinkage. The joints should be inserted where there are thickness changes and offsets. Ordinarily, joints should be spaced 30 ft on center or less in exposed structures, such as retaining walls.

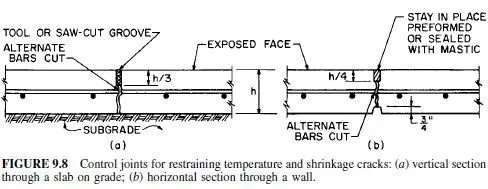

To avoid unsightly cracks due to shrinkage, a dummy-type contraction joint is frequently used (Fig. 9.8). When contraction takes place, a crack occurs at this deliberately made plane of weakness. In this way, the crack is made to occur in a straight line easily sealed.

Control joints may also consist of a 2- or 3-ft gap left in a long wall or slab, with the reinforcement from both ends lapped in the gap. Several weeks after the wall or slab has been concreted, the gap is filled with concrete. By that time, most of the shrinkage has taken place.

In expansion joints, a filler is usually provided to separate the two parts of the structure. This filler should be a compressive substance, such as corkboard or premolded mastic. The filler should have properties such that it will not be squeezed out of the joint, will not slump when heated by the sun, and will not stain the surface of the concrete.

To be waterproof, a joint must be sealed. For this purpose, copper flashing may be used. It is usually embedded in the concrete on both sides of the joint, and folded into the joint so that the joint may open without rupturing the metal. The flashing must be strong enough to hold its position when the concrete is cast.

Proprietary flexible water stops and polysulfide calking compounds may also be used as sealers.

Open expansion joints are sometimes used for interior locations where the opening is not objectionable. When exposed to water from above, as in parking decks, open joints may be provided with a gutter below to drain away water.

The engineer should show all necessary vertical and horizontal joints on design drawings. All pertinent details affecting reinforcement, water stops, and sealers should also be shown.

Construction joints should be designed and located if possible at sections of minimum shear. These sections will usually be at the center of beams and slabs, where the bending moment is highest. They should be located where it is most convenient to stop work. The construction joint is often keyed for shearing strength.

If it is not possible to concrete an entire floor in one operation, vertical joints preferably should be located in the center of a span. Horizontal joints are usually provided between columns and floor; columns are concreted first, then the entire floor system.

Various types of construction joints are shown in Fig. 9.9. The numbers on each section refer to the sequence of placing concrete.

If the joint is horizontal as in Fig. 9.9a, water may be trapped in the key of the joint. If the joint is vertical, the key is easily formed by nailing a wood strip to the inside of the forms. A raised key, as in Fig. 9.9b, makes formwork difficult for horizontal joints.

In the horizontal joint in Fig. 9.9c, the key is made by setting precastconcrete blocks into the concrete at intermittent intervals. The key in Fig. 9.9d

is good if the shear acts in the directions shown.

The V-shaped key in Fig. 9.9e can be made manually in the wet concrete for horizontal joints.

The key is eliminated in Fig. 9.9Æ’, reliance being placed on friction on the roughened surface. This method may be used if the shear forces are small, or if there are large compressive forces or sufficient

reinforcement across the joint.

See also Arts. 9.32 to 9.34.