The principal destroyers of wood are decay, caused by fungus, and attack by a number of animal organisms of which termites, carpenter ants, grubs of a wide variety of beetles, teredo, and limnoria are the principal offenders. In addition, fire annually causes widespread destruction of wood structures.

Decay will not occur if wood is kept well ventilated and air-dry or, conversely, if it is kept continuously submerged so that air is excluded.

Most termites in the United States are subterranean and require contact with the soil. The drywood and dampwood termites found along the southern fringes of the country and along the west coast, however, do not require direct soil contact and are more difficult to control.

Teredo, limnoria, and other water-borne wood destroyers are found only in salt or brackish waters.

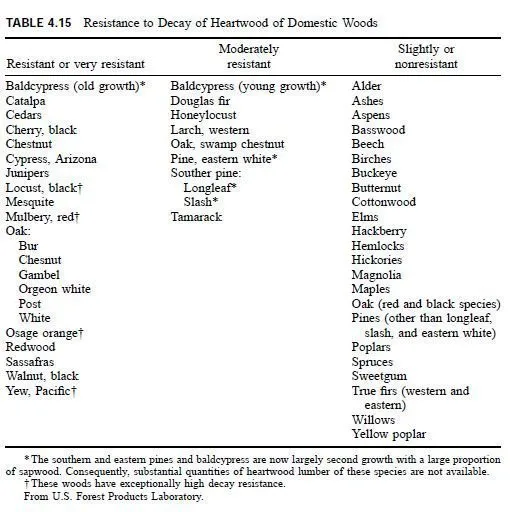

Various wood species vary in natural durability and resistance to decay and insect attack. The sapwood of all species is relatively vulnerable; only the heartwood can be considered to be resistant. Table 4.15 lists the common species in accordance with heartwood resistance. Such a list is only approximate, and individual pieces deviate considerably.

Preservatives employed to combat the various destructive agencies may be subdivided into oily, water-soluble salts, and solvent-soluble organic materials. The principal oily preservatives are coal-tar creosote and creosote mixed with petroleum.

The most commonly employed water-soluble salts are acid copper chromate, chromated copper arsenate and arsenite, fluor chrome arsenate phenol, chromated zinc chloride, and other materials that are often sold under various proprietary names.

The principal solvent-soluble organic materials are chlorinated phenols, such as pentachlorphenol, and copper naphthenate.

Preservatives may be applied in a variety of ways, including brushing and dipping, but for maximum treatment, pressure is required to provide deep side-grain penetration. Butts of poles and other parts are sometimes placed in a hot boiling creosote or salt solution, and after the water in the wood has been converted to steam, they are quickly transferred to a cold vat of the same preservative. As the steam condenses, it produces a partial vacuum, which draws the preservative fairly deeply into the surface.

Pressure treatments may be classified as full-cell and empty-cell. In the full-cell treatment, a partial vacuum is first drawn in the pressure-treating tank to with draw most of the air in the cells of the wood. The preservative is then let in without breaking the vacuum, after which pressure is applied to the hot solution. After treatment is completed, the individual cells are presumably filled with preservative.

In the empty-cell method, no initial vacuum is drawn, but the preservative is pumped in under pressure against the back pressure of the compressed air in the wood. When the pressure is released, the air in the wood expands and forces out excess preservative, leaving only a coating of preservative on the cell walls.

Retentions of preservative depend on the application. For teredo-infestation, fullcell creosote treatment to refusal may be specified, ranging from 16 to 20 lb per cubic foot of wood. For ordinary decay conditions and resistance to termites and other destroyers of a similar nature, the empty-cell method may be employed with retentions in the vicinity of 6 to 8 lb of creosote per cubic foot of wood. Salt retentions generally range in the vicinity of 11â„2 to 3 lb of dry salt retained per cubic food of wood.

Solvent-soluble organic materials, such as pentachlorphenol, are commonly employed for the treatment of sash and door parts to impart greater resistance to decay.

This is commonly done by simply dipping the parts in the solution and then allowing them to dry. As the organic solvent evaporates, it leaves the water-insoluble preservative behind in the wood.

These organic materials are also employed for general preservative treatment, including fence posts and structural lumber. The water-soluble salts and solventsoluble organic architects leave the wood clean and paintable. Creosote in general cannot be painted over, although partial success can be achieved with top-quality aluminum-flake pigment paints.

Treatment against fire consists generally of applying salts containing ammonium and phosphates, of which monoammonium phosphate and diammonium phosphate are widely employed. At retentions of 3 to 5 lb of dry salt per cubic foot, the wood does not support its own combustion, and the afterglow when fire is removed is short. A variety of surface treatments is also available, most of which depend on the formation of a blanket of inert-gas bubbles over the surface of the wood in the presence of flame or other sources of heat. The blanket of bubbles insulates the wood beneath and retards combustion.

See also Art. 10.6.

wow,damm good post