Column-to-column connections are usually determined by the change in section. In general, a change is made at every second floor level, where a shop or field splice is located. From an erection viewpoint, as well as for fabrication and shipment, splices at every third floor may be more economical because of the reduced number of pieces to handle. This advantage is partly offset by extra weight of column material, because the column size is determined by loads on the lowest story of each tier, there being an excess of section for the story or two above.

Splices are located just above floor-beam connections, usually about 2 to 3 ft above the floor. Because column stresses are transferred from column to column by bearing, the splice plates are of nominal size, commensurate with the need for safe erection and bending moments the joint may be subjected to during erection.

From the viewpoint of moment resistance, a conventional column splice develops perhaps 20% of the moment capacity of the column.

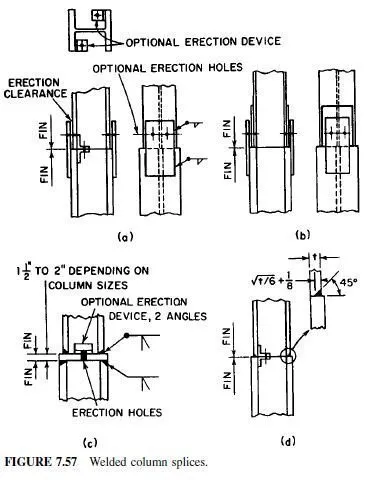

Figure 7.56 illustrates the common types of column splices made with high strength bolts. In Fig. 7.56a and b, the upper column bears directly on the lower column; filler plates are supplied in (b) when the differences in depth of the two columns are greater than can be absorbed by erection clearance.

As a rule, some erection clearance should be provided. When columns of the same nominal depth are spliced, it is customary to supply a 1â???8-in fill under each splice plate on the lower column, or, as an alternate, to leave the bolt holes open on the top gage line below the finished joint until the upper shaft is erected. The latter procedure permits the erector to spring the plates apart to facilitate entry of the upper column.

When the upper column is of such dimension that its finished end does not wholly bear on the lower column, one of two methods must be followed: In Fig. 7.56c, stresses in a portion of the upper column not bearing on the lower column are transferred by means of flange plates that are finished to bear on the lower column. These bearing plates must be attached with sufficient single-shear bolts to develop the load transmitted through bearing on the finished surface.

When the difference in column size is pronounced, the practice is to use a horizontal bearing plate as shown in Fig. 7.56d. These plates, known as butt plates, may be attached to either shaft with tack welds or clip angles. Usually it is attached to the upper shaft, because a plate on the lower shaft may interfere with erection of the beams that frame into the column web.

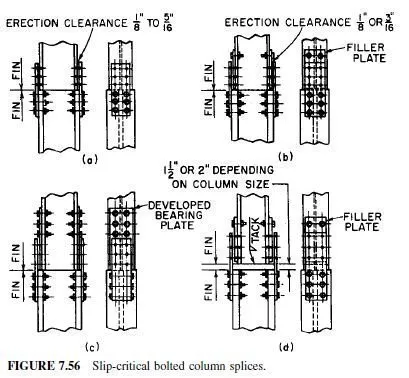

Somewhat similar are welded column splices. In Fig. 7.57a, a common case, holes for erection purposes are generally supplied in the splice plates and column flanges as shown. Some fabricators, however, prefer to avoid drilling and punching of thick pieces, and use instead clip angles welded on the inside flanges of the columns, one pair at diagonally opposite corners, or some similar arrangement, Figure 7.57b and c corresponds to the bolted splices in Fig. 7.56c and d. The shop and field welds for the welded butt plate in Fig. 7.57c may be reversed, to provide erection clearance for beams seated just below the splice. The erection clip angles would then be shop welded to the underside of the butt plate, and the field holes would pierce the column web.

The butt-weld splice in Fig. 7.57d is the most efficient from the standpoint of material saving. The depth of the bevel as given in the illustration is for the usual column splice, in which moment is unimportant. However, should the joint be subjected to considerable moment, the bevel may be deepened; but a 1â„8-in minimum shoulder should remain for the purpose of landing and plumbing the column. For full moment capacity, a complete-penetration welded joint would be required.

STEEL ERECTION

A clear understanding of what the fabricator furnishes or does not furnish to the erector, particularly on fabrication contracts that may call for delivery only, is all important and in many instances fabricated steel is purchased on delivery basis only.

Purchasing structural steel is simplified by the Code of Standard Practice for Buildings and Bridges, (Table 7.1). A provision in the construction contract making the code a part of the contract is often used, since it establishes a commonly accepted and well-defined line of demarcation between what is, and what is not, to be furnished under the contract. Lacking such a provision, the contract, to avoid later misunderstandings, must enumerate in considerable detail what is expected of both parties to the contract.

Under the code and unless otherwise specifically called for in the contract documents such items as steel sash, corrugated-iron roofing or siding, and openweb steel joists, and similar items, even if made of steel and shown on the contract design drawings, are not included in the category structural steel. Also, such items as door frames are excluded, even when made of structural shapes, if they are not fastened to the structure in such way as to comply with constituting part of the steel framing. On the other hand, loose lintels shown on design plans or in separate scheduling are included.

According to the code, a fabricator furnishes with structural steel, to be erected by someone else, the field bolts required for fastening the steel. The fab ricator, however, does not furnish the following items unless specified in the invitation to bid: shims, fitting-up bolts, drift pins, temporary cables, welding electrodes, or thin leveling plates for column bases.

The code also defines the erection practices. For example, the erector does not paint field boltheads and nuts, field welds, or touch up abrasions in the shop coat, or perform any other field painting unless required in specifications accompanying the invitation to bid.