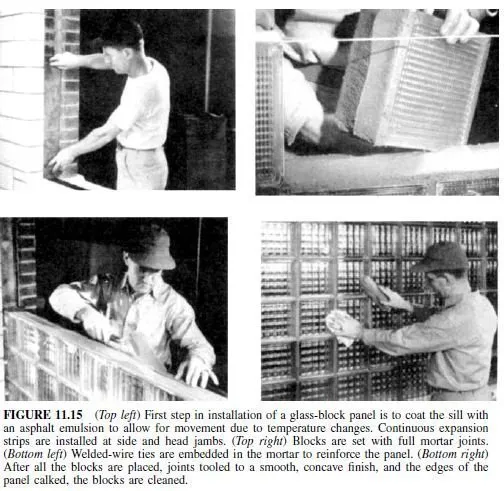

For control of light that enters a building and for better insulation than obtained with ordinary glass panes, masonry walls of glass block are frequently used (Fig. 11.15). These units are hollow, 37â„8 in thick by 6 in square, 8 in square, or 12 in square (actual length and height 1â„4 in less, for modular coordination, to allow for mortar joints). Faces of the units may be cut into prisms to throw light upward or the block may be treated to diffuse light.

Glass blocks may be used as nonbearing walls and to fill openings in walls. The glass block so used should have a minimum thickness of 3 in at the mortar joint.

Also, surfaces of the block should be satisfactorily treated for mortar bonding.

For exterior walls, glass-block panels should not have an unsupported area of more than 144 ft2. They should be no more than 15 ft long or high between supports.

For interior walls, glass-block panels should not have an unsupported area of more than 250 ft2. Neither length nor height should exceed 25 ft.

Exterior panels should be held in place in the wall opening to resist both internal and external wind pressures. The panels should be set in recesses at the jambs so as to provide a bearing surface at least 1 in wide along the edges. Panels more than 10 ft long should also be recessed at the head. Some building codes, however, permit anchoring small panels in low buildings with noncorrodible perforated metal strips.

Steel reinforcement should be placed in the horizontal mortar joints of glassblock panels at vertical intervals of 2 ft or less. It should extend the full length of the joints but not across expansion joints. When splices are necessary, the reinforcement should be lapped at least 6 in. In addition, reinforcement should be placed in the joint immediately below and above any openings in a panel.

The reinforcement should consist of two parallel longitudinal galvanized-steel wires, No.9 ga or larger, spaced 2 in apart, and having welded to them No.14 or heavier-gage cross wires at intervals up to 8 in.

Glass block should be laid in Type S mortar. Mortar joints should be from 1â„4 to 3â„8 in thick. They should be completely filled with mortar.

Exterior glass-block panels should be provided with 1â„2-in expansion joints at sides and top. These joints should be kept free of mortar and should be filled with resilient material (Fig. 11.15). An opening may be filled one block at a time, as in??Fig. 11.15, or with a preassembled panel.

STUD WALLS

Load-bearing walls in buildings up to three stories high and story-high partitions often are constructed of framing composed of thin pieces of wood or metal. When the main structural members of such walls are installed vertically at close spacing, the members are called studs and the walls are referred to as stud walls. Any of a wide variety of materials may be applied to the studs as facings for the walls.

Stud walls permit placement of insulation between studs, so that no increase in thickness is required to accommodate insulation. Also, pipe and conduit may be inexpensively hidden in the walls. Cost of stud construction is usually less than for all-masonry walls.