A pinned connection is used to permit rotation of the end of a connected member. Some aspects of the design of a pinned connection are the same as those of a bolted bearing connection. The pin serves the same purpose as the shank of a bolt. But since only one pin is present in a connection, forces acting on a pin are generally much greater than those on a bolt. Shear on a pin can be resisted by selecting a large enough pin diameter and an appropriate grade of steel. Bearing on thin webs or plates can be brought within allowable values by addition of reinforcing plates. Because a pin is relatively long, bending, ignored in bolts, must be investigated in choosing a pin diameter. Arrangements of plates on the pin affect bending stresses. Hence plates should be symmetrically placed and positioned to minimize stresses.

Finishing of the pin and its effect on bearing should be considered. Unless the pin is machined, the roundness tolerance may not permit full bearing, and a close fit of the pin may not be possible. The requirements of the pin should be taken into account before a fit is specified.

Pins may be made of any of the structural steels permitted by AISC, AASHTO, and

AREA specifications, ASTM A108 grades 1016 through 1030, and A668 classes C, D, F, and G.

Pins must be forged and annealed when they are more than 7 in in diameter for railroad bridges. Smaller pins may be forged and annealed or cold-finished carbon-steel shafting. In pins larger than 9 in in diameter, a hole at least 2 in in diameter must be bored full length along the axis. This work should be done after the forging has been allowed to cool to a temperature below the critical range, with precautions taken to prevent injury by too rapid cooling, and before the metal is annealed. The hole permits passage of a bolt with threaded ends for attachment of nuts or caps at the pin ends.

When reinforcing plates are needed on connected material, the plates should be arranged to reduce eccentricity on the pin to a minimum. One plate on each side should be as wide as the outstanding flanges will permit. At least one full-width plate on each segment should

extend to the far end of the stay plate. Other reinforcing plates should extend at least 6 in beyond the near edge. All plates should be connected with fasteners or welds arranged to transmit the bearing pressure uniformly over the full section.

In buildings, pinhole diameters should not exceed pin diameters by more than 1â„32 in. In bridges, this requirement holds for pins more than 5 in in diameter, but for smaller pins, the tolerance is reduced to 1â„50 in.

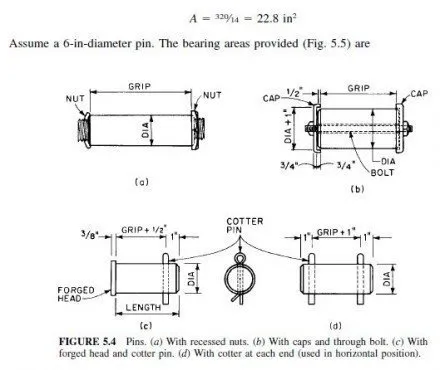

Length of pin should be sufficient to secure full bearing on the turned body of the pin of all connected parts. Pins should be secured in position and connected material restrained against lateral movement on the pins. For the purpose, ends of a pin may be threaded, and hexagonal recessed nuts or hexagonal solid nuts with washers may be screwed on them (Fig. 5.4a). Usually made of malleable castings or steel, the nuts should be secured by cotter pins in the screw ends or by burred threads. Bored pins may be held by a recessed cap at each end, secured by a nut on a bolt passing through the caps and the pin (Fig. 5.4b). In building work, a pin may be secured with cotter pins (Fig. 5.4c and d).

The most economical method is to drill a hole in each end for cotter pins. This, however, can be used only for horizontal pins. When a round must be turned down to obtain the required fit, a head can be formed to hold the pin at one end. The other end can be held by a cotter pin or threaded for a nut.

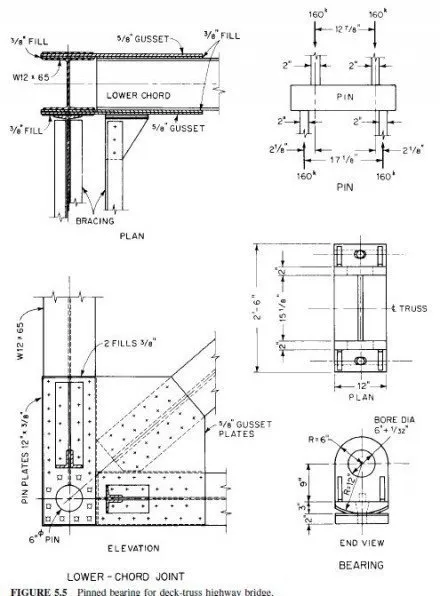

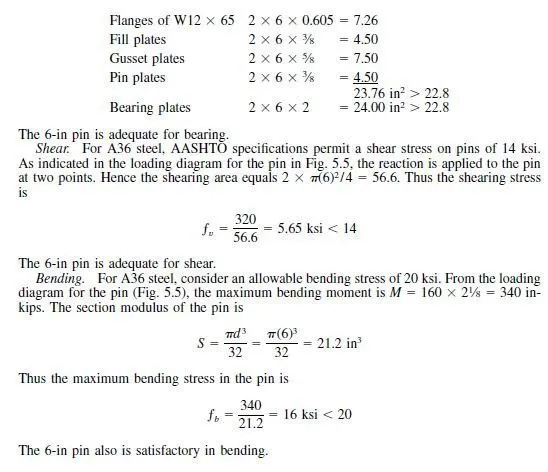

Example. Determine the diameter of pin required to carry a 320-kip reaction of a decktruss highway bridge (Fig. 5.5) using Allowable Stress Design (ASD).

Bearing. For A36 steel, American Association of State Highway and Transportation

Officials (AASHTO) specifications permit a bearing stress of 14 ksi on pins subject to rotation, such as those used in rockers and hinges. Hence the minimum bearing area on the pin must equal

GENERAL CRITERIA FOR BOLTED CONNECTIONS

Standard specifications for structural steel for buildings and bridges contain general criteria governing the design of bolted connections. They cover such essentials as permissible fastener size, sizes of holes, arrangements of fasteners, size and attachment of fillers, and installation methods.