In best engineering practice the engineer will produce complete bar-bending schedules for use by the contractor. The engineer may not guarantee that such schedules are error free and may call upon the contractor to check them. But, as often as not, the contractor will fail to do this, so it is advisable for the resident engineer to check the schedules so that he can forewarn the contractor of any error present. In practice, few errors will be found because the advantage of producing bar-bending schedules is that it applies a detailed check on the validity of the reinforcement drawings supplied to the contractor.

In some contracts the contractor is required to produce bar-bending schedules himself from the reinforcement drawings supplied under the contract.

This is not such good practice; the engineer foregoes an opportunity to check the reinforcement drawings, and the contractor (or his reinforcement supplier) who produces the bending schedules will not necessarily be sufficiently acquainted with the design to notice some discrepancy which indicates a possible design error.

Reinforcement is now seldom bent on site, except on sites overseas.

Deliveries of reinforcement should be supervised by the leading steelfixer, who should check the steel against the bar schedules and direct where bars should be stocked. Bars should be delivered with identifying tags on them, but sometimes these get torn off. The leading steelfixer should not allow with drawals from stock without his permission. If the contractor does not pay sufficient attention to this and, for example, lets various steelfixers pick what steel they think is right, the resident engineer should forewarn the contractor this is a recipe for ultimate chaos and delay.

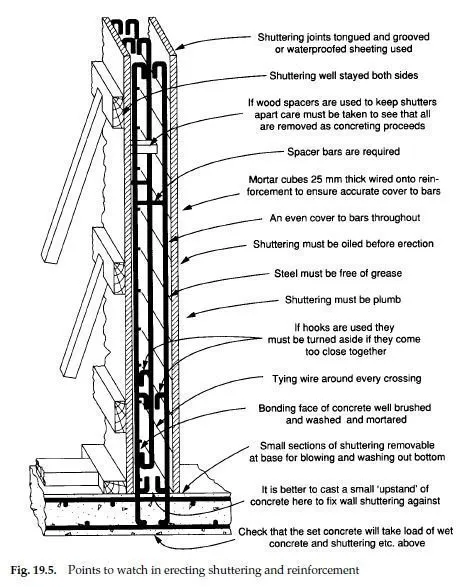

Properly designed and bent bars can, in the hands of a good steelfixer, be as accurately placed as formwork. Crossings of reinforcement have to be wired together so that a rigid cage is built, able to withstand concrete placing without displacement. To ensure that the correct cover is given to bars, the contractor will need to prepare many small spacer blocks of concrete of the requisite cover thickness and about 25 mm square, which are wired onto the outside of reinforcement, keeping it the required distance from the formwork to give the specified cover. All wire ties should be snipped off close to the reinforcement so that their ends do not penetrate the concrete cover and form a path for corrosion of the reinforcement. The steelfixer will need to make and position spacer bars, generally U-shaped, which keep reinforcement layers the correct distance apart in slabs and walls. He may need many of these.

They are not included in the bar-bending schedules and the cost to the contractor of supplying and fixing them is usually included in the price for

steelfixing. Fig. 19.5 shows some points to watch when formwork and reinforcement is being erected.

Steel reinforcement stored on site rusts, but provided the rust is not so advanced that rust scales are formed, the rust does not appear to affect the bonding of the reinforcement to the concrete. A problem more likely to arise is the contamination of steel reinforcement with oil, grease, or bitumen. If the contractor wishes to oil or grease formwork to prevent it sticking to concrete, he should do so before the formwork is erected and not after it has been put in place. If the latter is attempted it will be almost impossible to prevent some oil or grease getting onto the reinforcement. Similarly, if contraction joints are to be bitumen painted, care must be taken not to get bitumen on bars passing through such a joint.

The proper design and detailing of reinforcement makes a major contribution to the quality and durability of reinforced concrete. The designer must choose diameters, spacings and lengths of bars which not only meet the theoretical design requirements but which make a practical system for erection and concreting. Reinforcement to slabs must either be strong enough for the steel fixer to stand on, or spaced far enough apart for him to get a foot between bars onto the formwork below. Wall and column reinforcement must be large enough diameter that it does not tend to sag under its own weight.

Beam reinforcement should not be so congested that it will be difficult to get concrete to surround the bars without using a mix with too high a water content.

The designer should consider options of design available to avoid heavy congestion of bars. An experienced designer who understands site erection problems will make as much use as possible of the four most commonly used bar diameters 10, 12, 20 and 25 mm. He will appreciate that a 5 m long bar 25 mm diameter weighs about 20 kg, so that larger diameter or longer bars can be difficult for a steel fixer to handle on his own. For ease of handling, bars should not exceed 68 m length.

Bond laps have to be allowed for and should be at places which are convenient for the erection of formwork and for concreting. Starter bars in floor slabs are nearly always necessary for bonding to the reinforcement in walls.

The length of their vertical arm should not be longer than is necessary to provide adequate bond length and support the wall reinforcement so they present minimum impedance for slab concreting. If the designer wishes to use hooked bars, he should make sure that the thickness of slab or wall in which they are to be placed is sufficient to accommodate such hooks.

See from here civil engineers how we bend and fix steel reinforcement, and many others like fixing door frames and window frames etc