Fat lime and hydraulic limes are used for making lime mortar. If fat lime is used sand mixed is normally 2 to 3 times its volume. If hydraulic lime is used sand mixed is only 2 times the volume of lime. Lime is prepared by pounding, if quantity required is small or by grinding, if the required quantity is more.

Pounding: For pounding pits are formed in hard grands. The size of pit is usually 1.80 m long, 0.4 m wide and 0.5 m deep. It is provided with lining of bricks or stones. Lime and sand dry mixed with required proportion is placed in the pit. Small quantity of water is added at intervals. In each interval the mix is pounded with wooden pounders and mortar is turned up and down. The process is continued till uniform colour and desired consistancy is achieved.

Grinding: This is the better way of getting good mix. The grinding may be carried out in bullock driven grinding mill or in power driven grinding mill.

Figure 2.1 shows a typical bullock driven grinding mill. It consists of a circular trench of radius 3 to 4.5 m, 0.3 m wide and 0.4 m deep. A wooden shaft pivoted at centre carries a stone wheel of width just 50 mm to 100 mm less than that of trench. Bullock drive this wheel in the trench for grinding mortar. The dry mix is placed in the trench. Water is added gradually and bullock driven stone wheels grind the mix. A worker turns the mix up and down regularly. This method of preparing mortar needs 6 hours and can produce about 1.7 m3 of mortar.

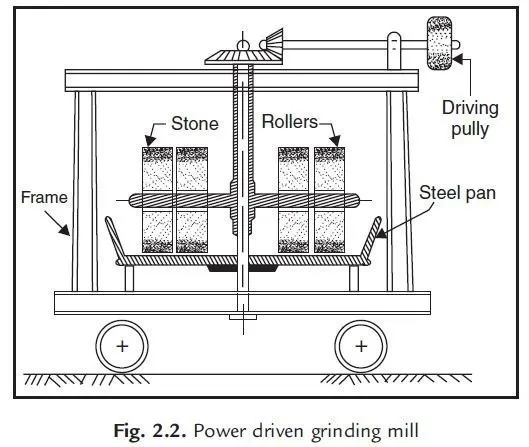

Figure 2.2 shows a typical power driven grinding mill used for preparing lime mortar. Two rollers rotate in a pan of diameter 1.8 to 2.4 m. Either pan or roller is rotated with the help of oil engine or electric power. During mixing required quantity of water is added gradually.