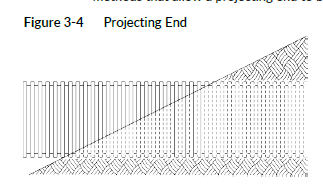

A projecting end is a treatment where the culvert is allowed to protrude out of the embankment (see Figure 3-4). The primary advantage of this type of end treatment is that it is the simplest and most economical of all treatments. Projecting ends also provide excellent strength characteristics because the pipe consists of a complete ring structure out to the culvert end.

Projecting ends have several disadvantages. For metal, the thin wall thickness does not provide flow transition into or out of the culvert, significantly increasing head losses (the opposite is true for concrete; the thicker wall provides a more efficient transition). From an aesthetic standpoint, projecting ends may not be desirable in areas exposed to public view. They should be used only when the culvert is located in the bottom of a ravine or in rural areas.

Modern safety considerations require that no projecting ends be allowed in the designated clear zone. (See WSDOT’s Design Manual for details on the clear zone and for methods that allow a projecting end to be used close to the traveled roadway.)

Metal culverts exceeding 6 feet in diameter but less than 10 feet in diameter, and all thermoplastic culverts, must be installed with a beveled end and a concrete headwall or slope collar as described in Sections 3-4.2 and 3-4.4. Concrete pipe will not experience buoyancy problems and can be projected in any diameter. However, because concrete pipe is fabricated in relatively short 6- to 12-foot sections, the sections are susceptible to erosion and corresponding separation at the first joint from the end.