Deteriorated pipes can affect the pipes’ structural integrity and lead to roadway failures and development of sinkholes. Pipe deterioration could include longitudinal or circular cracks, joint separations, root intrusions, deformation, erosion, voids outside the pipes, and bedding erosion. Depending on the type of deterioration, failure to repair deteriorated pipes within certain time frames , which can lead to roadway failures, embankment failures, or sinkhole development.

The most common option for a deteriorated pipe is to remove the existing culvert and replace it with a new one.

For locations where replacing the pipe is not feasible, it may be possible to use rehabilitation methods to restore the structural integrity of the pipe system, with minimal impact to roadway traffic. These methods are referred to as trenchless technology because minimal trenching is needed.

Prior to selecting a trenchless technology method, the PEO shall investigate the feasibility of a pipe being rehabilitated to provide a long-term fix. The investigation shall include, at a minimum:

• Evaluation of the pipe bedding and backfill conditions: The pipe bedding and backfill shall be evaluated to determine if the existing conditions meet current design criteria. For example, if the existing pipe has cracked, water may have leaked through the pipe wall and caused erosion of the bedding material. In this case, the void spaces may need to be grouted between the backfill and the host pipe prior to rehabilitation.

• Analysis of the hydraulic capacity of pipe: The hydraulic capacity of a rehabilitated pipe shall be analyzed using the same criteria required for a new pipe. This includes a complete basin analysis as the contributing area may have changed since the original pipe was designed. Also, many trenchless technologies involve methods that reduce the diameter of the host pipe. For crossing culverts, if the pipe diameter is reduced, it must be analyzed as a culvert. Evaluate the inlet or outlet control and upstream and downstream impacts, and maintain the minimum pipe diameter requirement. HDPE and PVC liners are typically strong enough to withstand the loads, and they can last more than 50 years. However, these liners would reduce the inside diameter of the pipes, and this could be an issue for crossing culverts. Minimum pipe diameters must be maintained. The Manning’s “n” values of HDPE and PVC liners are typically smaller than those of corrugated metal pipes and cement concrete pipes; therefore, flow capacity might not be an issue. However, flow capacity analysis is still required.

• Evaluation of the structural integrity of the pipe: The structural integrity of the pipe shall be evaluated to determine if the host pipe is strong enough to tolerate the trenchless technology. This will involve contacting the State Hydraulics Office for guidance on inspecting the pipe and developing a risk assessment. The vendors providing the trenchless technology should also be consulted for determining the minimum structural requirements of the pipe. When evaluating the structural integrity of the pipes, the host pipes are excluded in the calculation. The liners must be able to withstand the dead loads and live loads. All pipes under rails must be sleeved. Cured-in-place pipe (CIPP) liners are typically very thin, and they may not be able to withstand the loads as required. If selected, certification from the manufacturer is required to testify that the liner is capable of withstanding the loads.

• Evaluation of cost and age of the pipe: The rehabilitative cost shall be determined as well as the replacement the replacement cost. Determine the age of the pipe as well as its original design life when installed.

• Evaluation of design life: All liners must have a lifespan of 50 years or longer. Certification from the manufacturer is required.

• Evaluation of environmental impacts: All liners must not have negative impacts on the environment. Consult with HQ ESO and Hydraulics for review and approval.

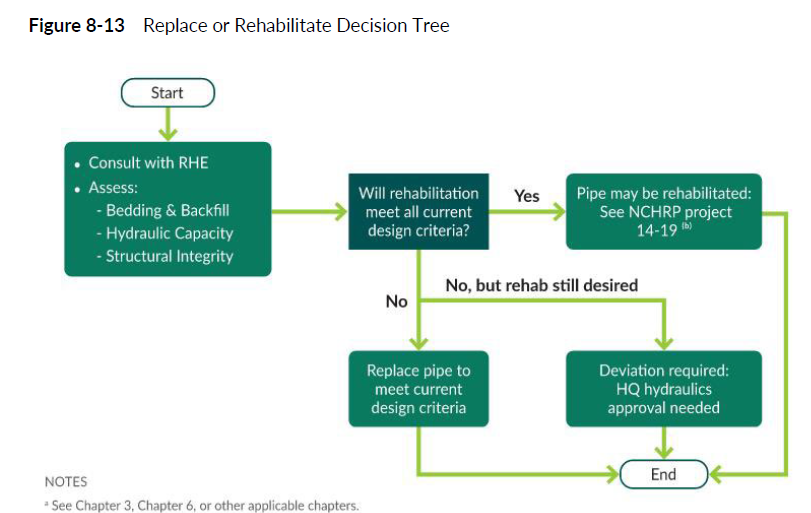

If this analysis indicates that rehabilitating the pipe using trenchless methods will meet all current design criteria, then the pipe may be rehabilitated. If the analysis indicates that the rehabilitated pipe will not meet current design criteria, then it must be replaced with one that does, or a deviation must be received from the State Hydraulics Office. See Figure 8-13.