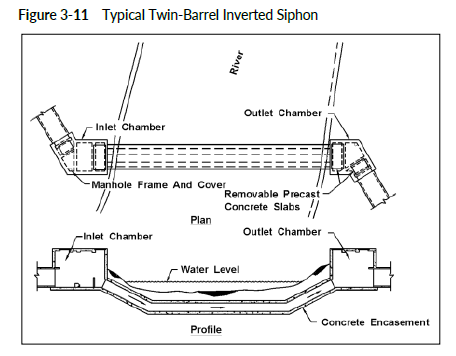

Siphon designs require review and concurrence by the State Hydraulics Office per Table 1-1. Also, the siphon design may need to be reviewed and approved by the owner of the features being crossed. A siphon carries the flow under an obstruction such as a depressed railroad, roadway, stream, sanitary sewer, water main, or any other structure or utility line that is in the path of the storm drain line. The storm drain invert is lowered at the obstacle and is raised again after the crossing. The siphon will remain full when there is no flow. AASHTO recommends a minimum of two barrels with 3 ft/s velocity. One of the barrels is designed to have a weir-type obstruction placed at the inlet and outlet structures to keep the normal flow in one barrel to provide the required minimum velocity for self-cleaning and servicing. The elevation of the weir crests is based on the depth of normal flows in the upstream storm drain. Maintenance access is to be provided at both the inlet and outlet chambers. Figure 3-11 illustrates a typical twin-barrel inverted siphon.

The following considerations from HEC-22, Chapter 6 (1) are important to the efficient design of siphons:

• Self-flushing velocities should be provided under a wide range of flows

• Hydraulic losses should be minimized

• Provisions for cleaning should be provided

• Sharp bends should be avoided

• The rising portion of the siphon should not be so steep as to make it difficult to flush deposits (some agencies limit the rising slope to 15 percent)

• There should be no change in pipe diameter along the length of the siphon

• Provisions for drainage should be considered

Additional information related to the design of siphons is provided in HEC-22 (1) and United States Bureau of Reclamation (USBR) Design of Small Canal Structures (6), which includes a design example.