Grate Types

Grates are an essential component in ensuring the efficiency of a drainage system. The following grates (except the rectangular herringbone grate) shall be used for new construction, where applicable.

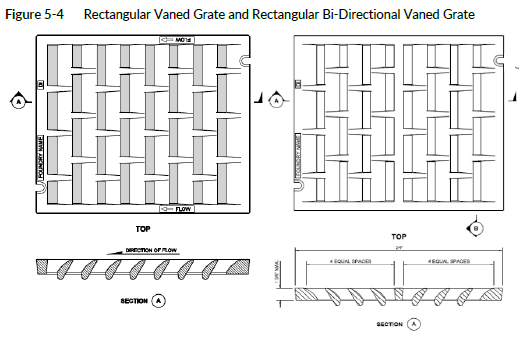

5-5.2.1 Rectangular Vaned Grate: Standard Plan B-30.30-03 and Rectangular Bi-Directional Vaned Grate: Standard Plan B-30.40-03

The vaned grate has a higher capacity for passing debris and shall be used in place of the herringbone grate in all new installations. Installation of the vaned grate is critical as the grate is directional. If installed backward the interception capacity is severely limited. The rectangular bi-directional vaned grate shall be used at all sump locations. Figure 5-4 depicts a rectangular vaned grate and a rectangular bi-directional vaned grate.

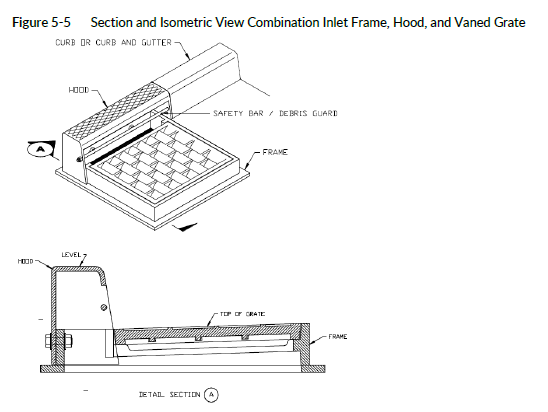

5-5.2.2 Combinations Inlet: Standard Plan B-25.20-02

The combination inlet is a vaned grate on a catch basin with a hooded curb cut area (Figure 5-5). The vaned grate is debris efficient, and, if the grate does become clogged, the overflow goes into the hooded opening. These inlets are useful for sag condition installations, although they can also be effective on continuous grades. The interception capacity of a combination inlet is only slightly greater than with a grate alone. Therefore, the capacity is computed neglecting the curb opening and the PEO should follow the same analysis as for a vaned grate alone (see Standard Plan B-30.30-03).

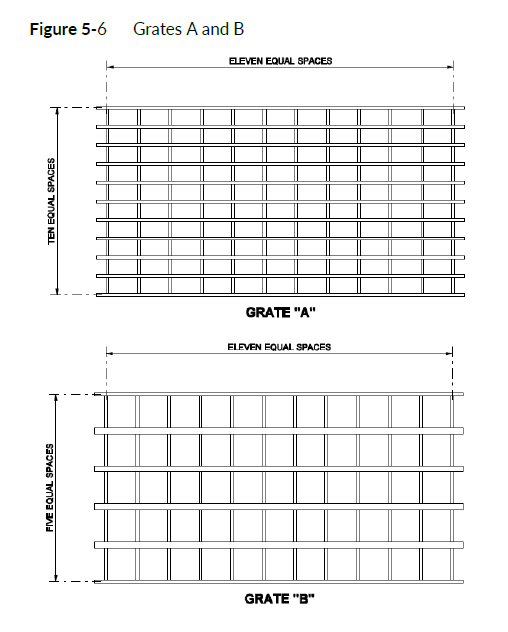

5-5.2.3 Welded Grates for Grate Inlet, Grate A and Grate B: Standard Plan B-40.20-00

Both welded grates (Types A and B) have large openings that can compensate for debris problems (Figure 5-6); however, there are limitations in their usage. Because of structural failure of Grates A and B, neither of these grates can be installed in heavy traffic areas where wheel loads will pass directly over. Grate B has large openings and is useful in ditches or non-paved median locations, in areas where there is no pedestrian or bicycle traffic. Grate A can be used anywhere Grate B is used as well as at the curb line of a wide interstate shoulder. Grate A may occasionally be subject to low-speed traffic or parked on, but it cannot withstand repeated interstate loading or turning vehicles.

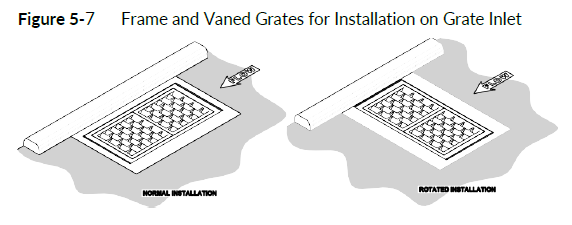

5-5.2.4 Frame and Dual Vaned Grates for Grate Inlet: Standard Plan B-40.40-02

Standard Plan B-40.40-02 has been tested in H-25 loading and was determined compatible with heavy traffic installations. This frame and double-vaned grate should be installed in a Unit H on top of a grate inlet Type 2 (Figure 5-7). The frame and vaned grates may be used in either new construction or retrofit situations. When used in areas of highway speeds, lockdown grates shall be specified. This grate can also be rotated 90 degrees to increase the flow interception capacity.

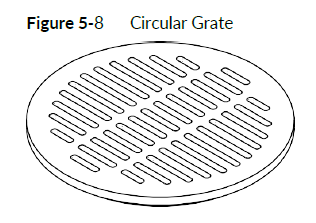

5-5.2.5 Circular Grate or Standard Plan B-30.80-01

Circular grates are intended for use with dry wells, see Standard Plans B-20.20-02 and B-20.60-03 for details (Figure 5-8). Install with circular frames (rings) as detailed in Standard Plan B-30.70-04.

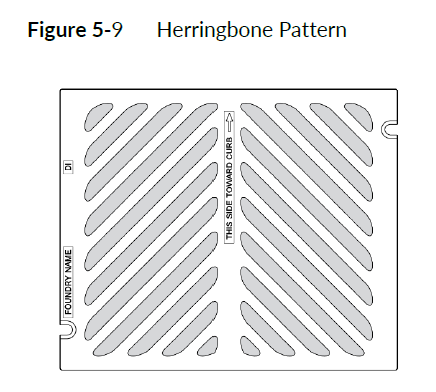

5-5.2.6 Rectangular Herringbone Grate: Standard Plan B-30.50-03

Herringbone grates (Figure 5-9) shall not be used on WSDOT projects. Replacement of existing herringbone gates should be considered during preservation projects. Historically, use of the vaned grate was limited because of cost considerations. The cost difference now is minimal; the vaned grate is bicycle safe and is hydraulically superior under most conditions.

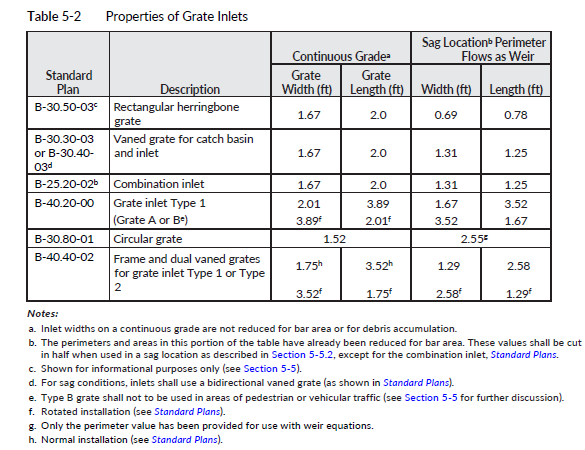

Grate inlet properties are summarized in Table 5-2.