2.1 Grain size

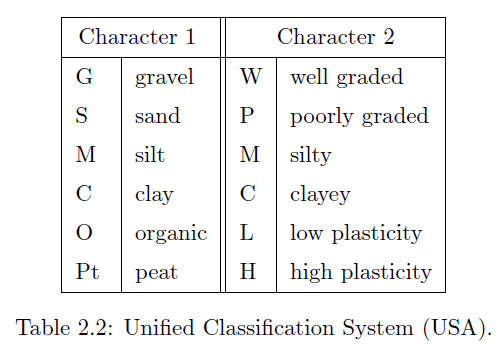

Soils are usually classified into various types. In many cases these various types also have different mechanical properties. A simple subdivision of soils is on the basis of the grain size of the particles that constitute the soil. Coarse granular material is often denoted as gravel and finer material as sand. In order to have a uniformly applicable terminology it has been agreed internationally to consider particles larger than 2 mm, but smaller than 63 mm as gravel. Larger particles are denoted as stones. Sand is the material consisting of particles smaller than 2 mm, but larger than 0.063 mm. Particles smaller than 0.063 mm and larger than 0.002 mm are denoted as silt. Soil consisting of even smaller particles, smaller than 0.002 mm, is denoted as clay or luthum, see Table 2.1. In some countries, such as the Netherlands, the soil may also contain layers of peat, consisting of organic material such as decayed plants. Particles of peat usually are rather small, but it may also contain pieces of wood. It is then not so much the grain size that is characteristic, but rather the chemical composition, with large amounts of carbon. The amount of carbon in a soil can easily be determined by measuring how much is lost when burning the material.

The mechanical behavior of the main types of soil, sand, clay and peat, is rather different. Clay usually is much less permeable for water than sand, but it usually is also much softer. Peat is usually is very light (some times hardly heavier than water), and strongly anisotropic because of the presence of fibers of organic material. Peat usually is also very compressible. Sand is rather permeable, and rather stiff, especially after a certain preloading. It is also very characteristic of granular soils such as sand and gravel, that they can not transfer tensile stresses. The particles can only transfer compressive forces, no tensile forces. Only when the particles are very small and the soil contains some water, can a tensile stress be transmitted, by capillary forces in the contact points.

The grain size may be useful as a first distinguishing property of soils, but it is not very useful for the mechanical properties. The quantitative data that an engineer needs depend upon the mechanical properties such as stiffness and strength, and these must be determined from mechanical tests. Soils of the same grain size may have different mechanical properties. Sand consisting of round particles, for instance, can have a strength that is much smaller than sand consisting of particles with sharp points. Also, a soil sample consisting of a mixture of various grain sizes can have a very small permeability if the small particles just fit in the pores between the larger particles.

The grain size may be useful as a first distinguishing property of soils, but it is not very useful for the mechanical properties. The quantitative data that an engineer needs depend upon the mechanical properties such as stiffness and strength, and these must be determined from mechanical tests. Soils of the same grain size may have different mechanical properties. Sand consisting of round particles, for instance, can have a strength that is much smaller than sand consisting of particles with sharp points. Also, a soil sample consisting of a mixture of various grain sizes can have a very small permeability if the small particles just fit in the pores between the larger particles.

The global character of a classification according to grain size is well illustrated by the characterization sometimes used in Germany, saying that gravel particles are smaller than a chicken’s egg and larger than the head of a match, and that sand particles are smaller than a match head, but should be visible to the naked eye.

2.2 Grain size diagram

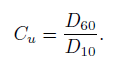

The size of the particles in a certain soil can be represented graphically in a grain size diagram, see Figure 2.1. Such a diagram indicates the percentage of the particles smaller than a certain diameter, measured as a percentage of the mass (or weight). A steep slope of the curve in the diagram indicates a uniform soil, a shallow slope of the diagram indicates that the soil contains particles of strongly different grain sizes. For rather coarse particles, say larger than 0.05 mm, the grain size distribution can be determined by sieving. The usual procedure is to use a system of sieves having different mesh sizes, stacked on top of each other, with the coarsest mesh on top and the finest mesh at the bottom, see Figure 2.2. After shaking the assembly of sieves, by hand or by a shaking machine, each sieve will contain the particles larger than its mesh size, and smaller than the mesh size of all the sieves above it. In this way the grain size diagram can be determined. Special standardized sets of sieves are available, as well as convenient shaking machines. The example shown i n Figure 2.1 illustrates normal sand. In this case there appear to be no grains larger than 5 mm. The grain size distribution can be characterized by the quantities D60 and D10. These indicate that 60 %, respectively 10 % of the particles (expressed as weights) is smaller than that diameter. In the case illustrated in Figure 2.1 it appears that D60 ~ 0.6 mm, and D10 ~ 0.07 mm. The ratio of these two numbers is denoted as the uniformity coefficient Cu,

n Figure 2.1 illustrates normal sand. In this case there appear to be no grains larger than 5 mm. The grain size distribution can be characterized by the quantities D60 and D10. These indicate that 60 %, respectively 10 % of the particles (expressed as weights) is smaller than that diameter. In the case illustrated in Figure 2.1 it appears that D60 ~ 0.6 mm, and D10 ~ 0.07 mm. The ratio of these two numbers is denoted as the uniformity coefficient Cu,

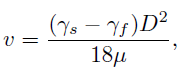

For particles smaller than about 0.05 mm the grain size can not be determined by sieving, because the size of the holes in the mesh would become unrealistically small, and also because during shaking the small particles might fly up in the air, as dust. The amount of particles of a particular size can then be determined much better by measuring the velocity of deposition in a glass of water. This method is based upon a formula derived by Stokes. This formula expresses that the force on a small sphere, sinking in a viscous fluid, depends upon the viscosity of the fluid, the size of the sphere and the velocity. Because the force acting upon the particle is determined by the weight of the particle under water, the velocity of sinking of a particle in a fluid can be derived. The formula is where Ys is the volumetric weight of the solid particles, f is the volumetric weight of the fluid, D is the grain size, and µ is the dynamic viscosity of the fluid. Because for very small particles the velocity may be very small, the test may take rather long.

where Ys is the volumetric weight of the solid particles, f is the volumetric weight of the fluid, D is the grain size, and µ is the dynamic viscosity of the fluid. Because for very small particles the velocity may be very small, the test may take rather long.

2.3 Chemical composition

Besides the difference in grain size, the chemical composition of soil can also be helpful in distinguishing between various types of soils. Sand and gravel usually consist of the same minerals as the original rock from which they were created by the erosion process. This can be quartz, feldspar or glimmer. In Western Europe sand usually consists mainly of quartz. The chemical formula of this mineral is SiO2.

Fine-grained soils may contain the same minerals, but they also contain the so-called clay minerals, which have been created by chemical erosion. The main clay minerals are kaolinite, montmorillonite and illite. In the Netherlands the most frequent clay mineral is illite. These minerals consist of compounds of aluminum with hydrogen, oxygen and silicates. They differ from each other in chemical composition, but also in geometrical structure, at the microscopic level. The microstructure of clay usually resembles thin plates. On the microscale there are forces between these very small elements, and ions of water may be bonded. Because of the small magnitude of the elements and their distances, these forces include electrical forces and the Van der Waals forces.

Although the interaction of clay particles is of a different nature than the interaction between the much larger grains of sand or gravel, there are many similarities in the global behavior of these soils. There are some essential differences, however. The deformations of clay are time dependent, for instance. When a sandy soil is loaded it will deform immediately, and then remain at rest if the load remains constant. Under such conditions a clay soil will continue to deform, however. This is called creep. It is very much dependent upon the actual chemical and mineralogical constitution of the clay. Also, some clays, especially clays containing large amounts of montmorillonite, may show a considerable swelling when they are getting wetter.

As mentioned before, peat contains the remains of decayed trees and plants. Chemically it therefore consists partly of carbon compounds. It may even be combustible, or it may be produce gas. As a foundation material it is not very suitable, also because it is often very light and compressible. It may be mentioned that some clays may also contain considerable amounts of organic material.

For a civil engineer the chemical and mineralogical composition of a soil may be useful as a warning of its characteristics, and as an indication of its difference from other materials, especially in combination with data from earlier projects. A chemical analysis does not give much quantitative information on the mechanical properties of a soil, however. For the determination of these properties mechanical tests, in which the deformations and stresses are measured, are necessary. These will be described in later chapters.

2.4 Consistency limits

For very fine soils, such as silt and clay, the consistency is an important property. It determines whether the soil can easily be handled, by soil moving equipment, or by hand. The consistency is often very much dependent on the amount of water in the soil. This is expressed by the water content w (see also chapter 3). It is defined as the weight of the water per unit weight of solid material,

When the water content is very low (as in a very dry clay) the soil can be very stiff, almost like a stone. It is then said to be in the solid state. Adding water, for instance if the clay is flooded by rain, may make the clay plastic, and for higher water contents the clay may even become almost liquid. In order to distinguish between these states (solid, plastic and liquid) two standard tests have been agreed upon, that indicate the consistency limits. They are sometimes denoted as the Atterberg limits, after the Swedish engineer who introduced them.

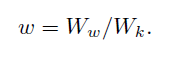

The transition from the liquid state to the plastic state is denoted as the liquid limit, wL. It represents the lowest water content at which the soil behavior is still mainly liquid. As this limit is not absolute, it has been defined as the value determined in a certain test, due to Casagrande, see Figure 2.3. In the test a hollow container with a soil sample may be raised and dropped by rotating an axis. The liquid limit is the value of the water content for which a standard V-shaped groove cut in the soil, will just close after 25 drops. When the groove closes after less than 25 drops, the soil is too wet, and some water must be allowed to evaporate. By waiting for some time, and perhaps mixing the clay some more, the water content will have decreased, and the test may be repeated, until the groove is closed after precisely 25 drops. Then the water content must immediately be determined, before any more water evaporates, of course.

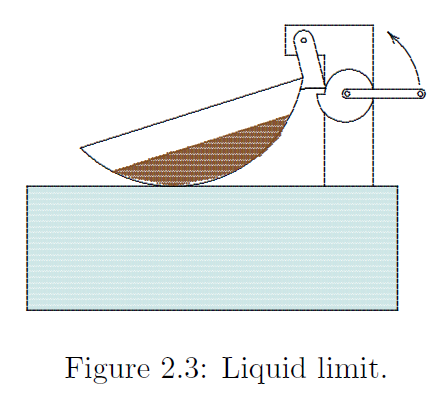

An alternative for Casagrande’s test is the fall cone, see Figure 2.4. In this test a steel cone, of 60 grams weight, and having a point angle of 60(degree), is placed upon a clay sample, with the point just at the surface of the clay. The cone is then dropped and its penetration depth is measured. The liquid limit has been defined as the water content corresponding to a penetration of exactly 10 mm. Again the liquid limit can be determined by doing the test at various water contents. It has also been observed, however, that the penetration depth, when plotted on a logarithmic scale, is an approximately linear function of the water content. This means that the liquid limit may be determined from a single test, which is much faster, although less accurate.

The transition from the plastic state to the solid state is called the plastic limit, and denoted as wP . It is defined as the water content at which the clay can just be rolled to threads of 3 mm diameter. Very wet clay can be rolled into very thin threads, but dry clay will break when rolling thick threads. The (arbitrary) limit of 3 mm is supposed to indicate the plastic limit. In the laboratory the test is performed by starting with a rather wet clay sample, from which it is simple to roll threads of 3 mm. By continuous rolling the clay will gradually become drier, by evaporation of the water, until the threads start to break.

For many applications (potteries, dike construction) it is especially important that the range of the plastic state is large. This is described by the plasticity index PI. It is defined as the difference of the liquid limit and the plastic limit,

PI = wL – wP .

The plasticity index is a useful measure for the possibility to process the clay. It is important for potteries, for the construction of the clay core in a high dam, and for the construction of a layer of low permeability covering a deposit of polluted material. In all these cases a high plasticity index indicates that the clay can easily be used without too much fear of it turning into a liquid or a solid.

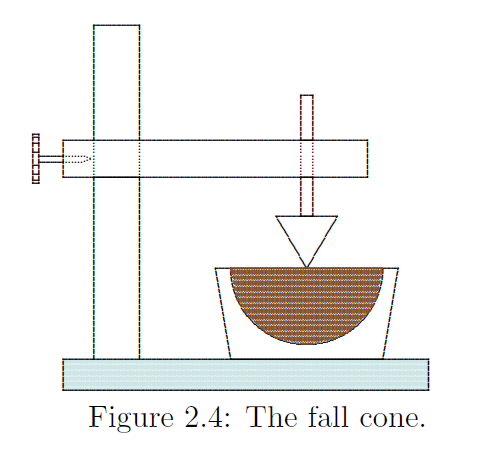

In countries with very thick clay deposits (England, Japan, Scandinavia) it is often useful to determine a profile of the plastic limit and the liquid limit as a function of depth, see Figure 2.5. In this diagram the natural water content, as determined by taking samples and immediately determining the water content, can also be indicated.

2.5 An international classification system

The large variability of soil types, even in small countries such as the Netherlands, leads to large variations in soil properties in soils that may resemble each other very much at first sight. This is enhanced by confusion between terms such as sandy clay and clayey sand that may be used by local firms. In some areas tradition may have also lead to the use of terms such as blue clay or brown clay, that may be very clear to experienced local engineers, but have little meaning to others.

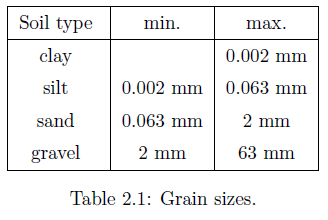

Uniform criteria for the classification of soils do not exist, especially because of local variations and characteristics. The soil in a plane of Tibet may be quite different from the soil in Bolivia or Canada, as their geological history may be quite different. The engineer should be aware of such differences and remain open to characterizations that are used in other countries. Nevertheless, a classification system that has been developed by the United States Bureau of Reclamation, is widely used all over the world. This system consists of two characters to indicate a soil type, see Table 2.2. A soil of type SM, for instance, is a silty sand, which indicates that it is a sand, but containing considerable amounts of non-organic fine silty particles. This type of soil is found in the Eastern Scheldt in the Netherlands. The sand on the beaches of the Netherlands usually is of the type SW. A clay of very low plasticity, that is a clay with a relatively small plasticity index is denoted as CL. The clay in a polder in Holland will often be of the type CH. It has a reasonably large range of plastic behavior. The characterization well graded indicates that a granular material consists of particles that together form a good framework for stress transfer. It usually is relatively stiff and strong, because the smaller particles fill well in the pores between the larger particles. A material consisting of large gravel particles and fine sand is called poorly graded, because it has little coherence. A well graded material is suitable for creating a road foundation, and is also suitable for the production of concrete. Global classifications as described above usually have only little meaning for the determination of mechanical properties of soils, such as stiffness and strength. There may be some correlation between the classification and the strength, but this is merely indicative. For engineering calculations mechanical tests should be performed, in which stresses and deformations are measured. Such tests are described in later chapters.