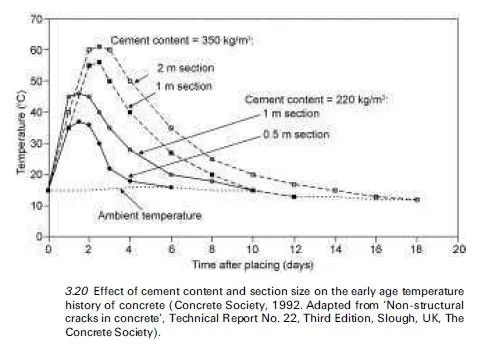

In large elements of concrete, the rate of heat development due to hydration of cement in the first one to three days after casting is likely to exceed the rate of heat loss to the atmosphere, causing the temperature in the concrete to rise. Thermal expansion thus occurs, which is followed by thermal contraction later as the concrete cools. Typical early age temperature histories are shown in Fig. 3.20, where the influences of both an increase in cement content and in section size of the element are seen to increase the peak temperature. Internal stress will be set up in the concrete due to restraints of thermal movement as it is virtually impossible to construct large concrete mass without restraints. They take the forms of internal restraint due to the different rates of heating and cooling between the core and surface of the concrete section, and external restraint caused by casting on, or adjacent to, previously hardened concrete. The presence of steel reinforcement also provides restraint, but this can be beneficial rather than detrimental. Reinforcement that is uniformly distributed and situated near the surface of the concrete can be utilised to control the width and number of cracks.