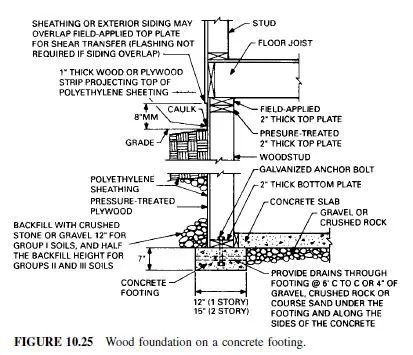

Plywood and lumber walls are an alternative to concrete for foundation walls for one-story and multistory houses and other light-frame buildings. Main components of a wood foundation wall are plywood, 5â„8 in or more thick, and wood studs, spaced 12 in or more on centers, both pressure-treated with preservative (Fig. 10.25). Some advantages of a wood foundation over concrete are faster construction, because there is no delay due to the wait for concrete or unit masonry to cure, easier interior finishing, because wood foundations provide nailable studs for the usual finishes, the ability to erect the system in virtually any weather, and generally drier basements due to the use of gravel backfill, which facilitates drainage of water away from the foundation. Wood basements also are much warmer and more comfortable for the occupant in cold weather.

Plywood should be an exterior type or an interior type that has been bonded with exterior glue, both types manufactured to meet the requirements of U.S. Product Standard PS 1 for Construction and Industrial Plywood. Lumber should be grade marked by an approved inspection agency, should be capable of accepting pressure preservative treatment, and should be of a species for which allowable design values are given in Art. 10.3.

Treatment for the plywood and lumber involves impregnating into the wood under heat and pressure ammoniacal copper arsenate or chromated copper arsenate (A, B, or C). Salt retention should be at least 0.60 lb / ft3 of wood, 50% more than building codes usually require for ground-contact applications. After pressure treatment, plywood should be dried to a moisture content of 18% or less, and lumber, to 19% or less. Portions of the wall more than 8 in above the ground, however, need not be pressure treated. If any of the materials have to be cut after treatment, the cut edges, unless they will be 8 in or more above grade, should be field treated with the preservatives used in the original treatment but with a minimum concentration of 3% in solution. To minimize end cutting and field treatment of footing plates, these members may be extended past the corners of the foundation.

Only corrosion-resistant fasteners should be used in wood foundations.

To keep the interior of the foundation walls dry, it is necessary to enclose the exterior with a waterproofing membrane, such as polyethylene film, and to ensure good drainage. For the latter purpose, the ground surface should be sloped away from the building at 1â„2 in / ft for a distance of at least 6 ft and gravel should be placed against the walls and under the cellar floor.

(See Permanent Wood Foundation System Technical Report 7 American Forest & Paper Association; Permanent Wood Foundations Design and Construction Guide, Southern Forest Products Association, for additional information.)