Once a PEO has determined the pipe classification needed for an application, the next step is to ensure that the pipe durability will extend for the entire design life. Pipe durability can be evaluated by determining the corrosion and abrasion potential of a given site and then choosing the appropriate pipe material and protective treatment for that location.

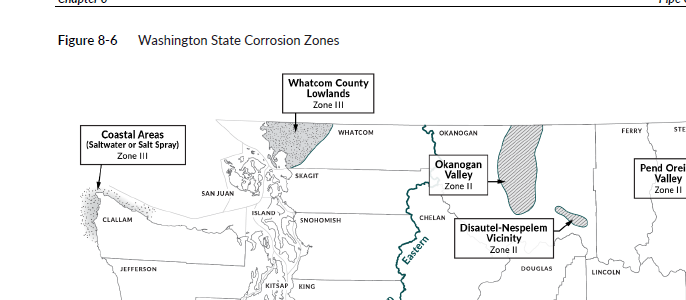

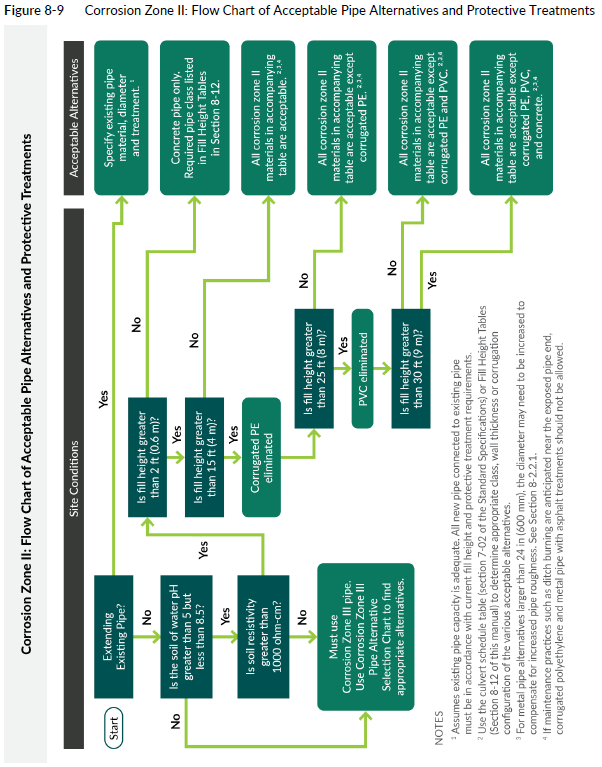

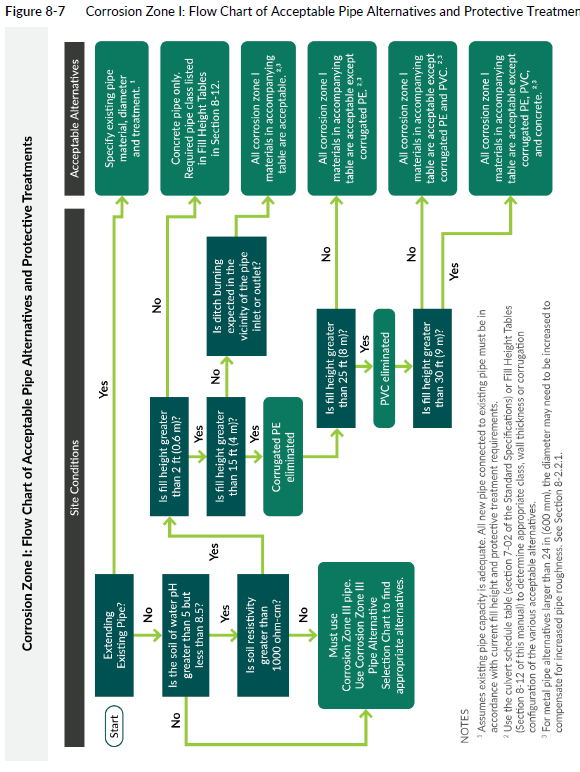

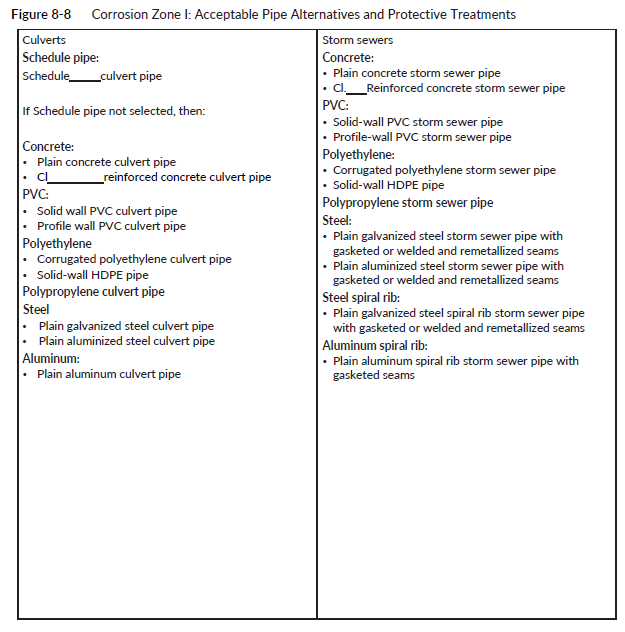

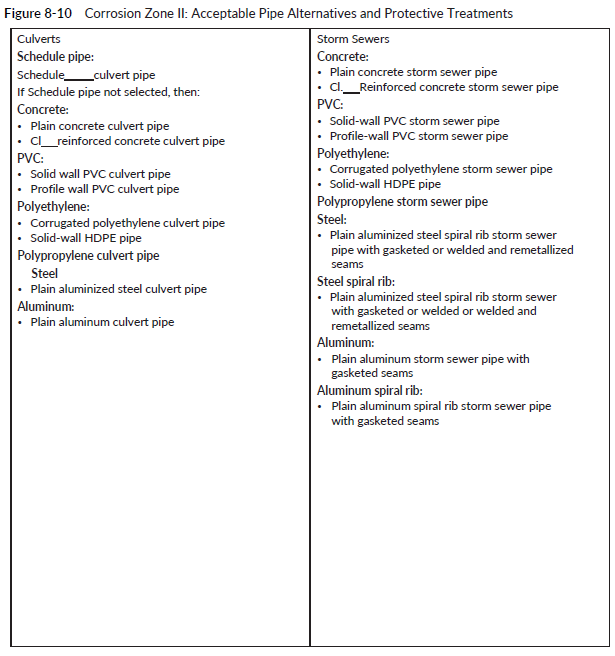

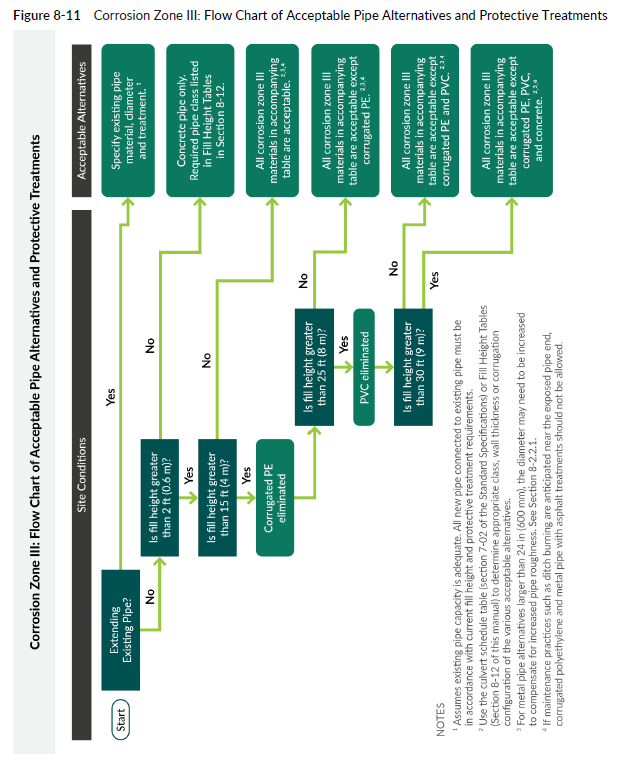

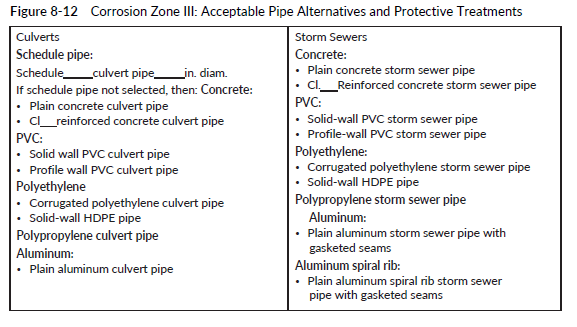

To simplify this process, Washington State has been divided into three corrosion zones, based upon the general corrosive characteristics of that particular zone. A map delineating the three zones is shown in Figure 8-6. A flow chart and corresponding acceptable pipe alternative list have been developed for each of the corrosion zones and are shown in Figure 8-7 through Figure 8-12. The flow charts and pipe alternative lists can be used to develop acceptable pipe alternatives for a given location.

The flow charts and pipe alternative lists do not account for abrasion, as bed loads moving through pipes can quickly remove asphalt coatings applied for corrosion protection. If abrasion is expected to be significant at a given site, the guidelines discussed in Table 8-1 shall be followed.

When selecting a pipe alternative, the PEO should consider the degree of difficulty that will be encountered in replacing a pipe at a future date. Drain pipes are relatively shallow and are readily replaced. Culverts tend to have greater depth of cover and pass under the highway alignment, making them more difficult to replace. Storm sewers are generally used in congested urban areas with significant pavement cover, high traffic use, and a multitude of other buried utilities in the same vicinity. For these reasons, storm sewers are generally considered to be the most expensive and most difficult to replace and should have a long design life.

When special circumstances exist (i.e., extremely high fills or extremely expensive structure excavation) the PEO should use good engineering judgment to justify the cost-effectiveness of a more expensive pipe option or a higher standard of protective treatment than is recommended on the figures in this section.

8-4.1 Corrosion Zone I

With the exceptions noted below, Corrosion Zone 1 encompasses most of eastern Washington and is considered the least corrosive part of the state. Plain galvanized steel, untreated aluminized steel, aluminum alloy, thermoplastic, and concrete pipe may all be used in Corrosion Zone I. (See Figure 8-7 and Figure 8-8 for a complete listing of acceptable pipe alternatives for culvert and storm sewer applications.)

The following parts of eastern Washington that are not within Corrosion Zone I are categorized as Corrosion Zone II:

• Okanogan Valley

• Pend Oreille Valley

• Disautel-Nespelem vicinity

8-4.2 Corrosion Zone II

Most of western Washington, with the exceptions noted below, along with the three areas of eastern Washington identified above make up Corrosion Zone II. This is an area of moderate corrosion activity. Untreated aluminized steel, aluminum alloy, thermoplastic, and concrete pipe may be used in Corrosion Zone II. (See Figure 8-9 and sewer applications.)

Parts of western Washington that are not within Corrosion Zone II are placed into Corrosion Zone III:

1. Whatcom County lowlands, described by the following:

a. State Route (SR) 542 from its origin in Bellingham to the junction of SR 9

b. SR 9 from the junction of SR 542 to the international boundary

c. All other roads/areas lying northerly and westerly of the above routes

2. Lower Nisqually Valley

3. Low-lying roadways in the Puget Sound basin and coastal areas subjected to the influence of saltwater bays, marshes, and tide flats. As a general guideline, this should include areas with elevations less than 20 feet above the average high tide elevation. Along the Pacific coast and the Straits of Juan de Fuca, areas within 300 to 600 feet of the edge of the average high tide can be influenced by salt spray and should be classified as Corrosion Zone III. However, this influence can vary significantly, depending on the roadway elevation and the presence of protective bluffs or vegetation. In these situations, the PEO is encouraged to evaluate existing pipes near the project to determine the most appropriate corrosion zone designation.

8-4.3 Corrosion Zone III

The severely corrosive areas identified above make up Corrosion Zone III. Concrete and thermoplastic pipe are allowed for use in this zone without protective treatments. Aluminum alloy is permitted only as described in Section 8-3. (See Figure 8-11 and Figure 8-12 for a complete listing of all acceptable pipe alternatives for culvert and storm sewer applications.)