This section presents pipe design alternatives.

8-10.1 Categories of Structural Materials: Rigid or Flexible

Based upon material type, pipes can be divided into two broad structural categories: flexible and rigid. Flexible pipes have little structural bending strength. The material they are made of, such as corrugated metal or thermoplastic, can be flexed or distorted significantly without cracking. Flexible pipes depend on support from the backfill to resist bending. Rigid pipes are stiff and do not deflect appreciably. The material they are made of, such as concrete, provides the primary resistance to bending.

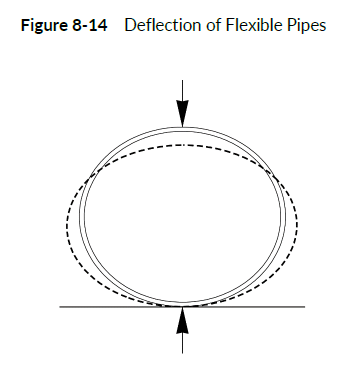

8-10.2 Structural Behavior of Flexible Pipes

A flexible pipe is a composite structure made up of the pipe barrel and the surrounding soil. The barrel and soil are both vital elements to the structural performance of the pipe. Flexible pipe has relatively little bending stiffness or bedding strength on its own. As loads are applied to the pipe, the pipe attempts to deflect. In the case of round pipe, the vertical diameter decreases and the horizontal diameter increases, as shown in Figure 8-14. When adequate soil support and backfill material are well compacted around the pipe, the increase in the horizontal diameter of the pipe is resisted by the lateral soil pressure. The result is a relatively uniform radial pressure around the pipe, which creates a compressive force in the pipe walls called thrust. To ensure that a stable soil envelope around the pipe is attained during construction, follow the guidelines in Section 8-10.4 for backfill and installation.

As vertical loads are applied, a flexible culvert attempts to deflect. The vertical diameter decreases while the horizontal diameter increases. Soil pressures resist the increase in horizontal diameter. The thrust can be calculated, based on the diameter of the pipe and the load placed on the top of the pipe, and is then used as a parameter in the structural design of the pipe.

The flexibility of a pipe also allows for some bend in the horizontal when designing the pipe layout. The PEO shall limit the bend to a maximum of 1.5 degrees. This same allowable bend does not apply to pipe profiles, which shall be designed to be straight. When bends occur in the profile, “bellies” form that cause sediment to accumulate.

The flexibility of a pipe also allows for some bend in the horizontal when designing the pipe layout. The PEO shall limit the bend to a maximum of 1.5 degrees. This same allowable bend does not apply to pipe profiles, which shall be designed to be straight. When bends occur in the profile, “bellies” form that cause sediment to accumulate.

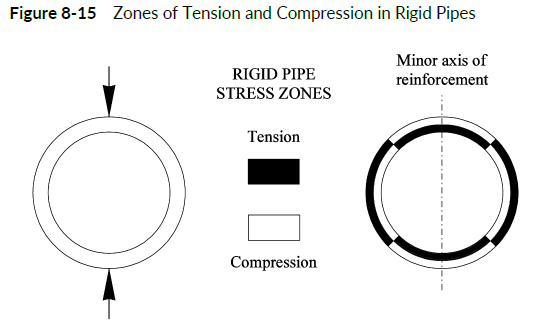

8-10.3 Structural Behavior of Rigid Pipes

The load-carrying capability of rigid pipes is essentially provided by the structural strength of the pipe itself, with some additional support given by the surrounding bedding and backfill. When vertical loads are applied to a rigid pipe, zones of compression and tension are created as illustrated in Figure 8-15. Reinforcing steel can be added to the tension zones to increase the tensile strength of concrete pipe. The minor axis for elliptical reinforcement is discussed in Section 8-3.1.

Rigid pipe is stiffer than the surrounding soil and it carries a substantial portion of the applied load. Shear stress in the haunch area can be critical for heavily loaded rigid pipe on hard foundations, especially if the haunch support is inadequate. Standard Plan B-55.20-03 and the Standard Specifications describe the backfill material requirements and installation procedures required for placing the various types of pipe materials. The fill height tables for concrete pipe shown in Section 8-12 were developed assuming that those requirements were followed during installation.

8-10.4 Foundations, Bedding, and Backfill

A foundation capable of providing uniform and stable support is important for both flexible and rigid pipes. The foundation must be able to uniformly support the pipe at the proposed grade and elevation without concentrating the load along the pipe. Establishing a suitable foundation requires removal and replacement of any hard spots or soft spots that would result in load concentration along the pipe.

Bedding is needed to level out any irregularities in the foundation and to ensure adequate compaction of the backfill material. (See the Standard Plans for Pipe Zone Bedding and Backfill and the Standard Specifications Backfilling for guidelines.) Any trenching conditions not described in the Standard Plans or Standard Specifications require approval from the State Hydraulics Office.

The bedding equal to one-third of the pipe outside diameter should be loosely placed directly under the pipe, while the remainder shall be compacted to a minimum 90 percent of maximum density per AASHTO guidelines. The importance of proper backfill for flexible and rigid pipe is discussed in Sections 8-10.2 and 8-10.3, respectively.

The bedding and backfill must also be installed properly to prevent piping from occurring. Piping is a term used to describe the movement of water around and along the outside of a pipe, washing away backfill material that supports the pipe. Piping is primarily a concern in culvert applications, where water at the culvert inlet can saturate the embankment and move into the pipe zone. Piping can be prevented through the use of headwalls, dikes, or plugs. Headwalls are described in Chapter 3 and dikes and plugs are discussed in the Standard Specifications.

To simplify measurement and payment during construction, all costs associated with furnishing and installing the bedding and backfill material within the pipe zone are included in the unit contract price of the pipe.