Once the type of rock has been selected from Table 4-2, the next step is to determine the appropriate installation. Several factors affect the placement of rock including the type of filter material best suited for the project site, the thickness of rock placement, and the depth to key rock to prevent undermining.

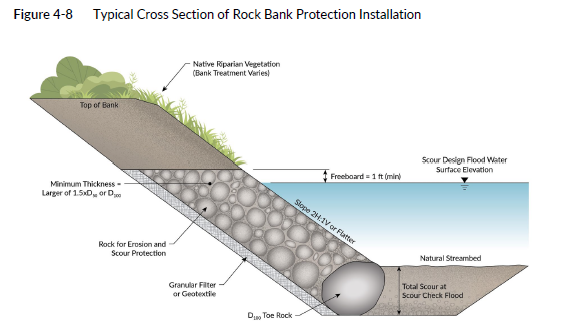

Figure 4-8 illustrates a typical cross section of a rock bank protection installation.

The filter material acts as a transition between the native soil and the rock, preventing the piping of fines through the voids of the rock structure while allowing relief of the hydrostatic pressure in the soil. Two types of filters are used: granular or geotextile. Filter materials are further described in the Standard Specifications and the Geotechnical Design Manual. If the existing banks are similar to the filter material of sands and gravel, no filter layer may be needed.

The proper selection of a filter material is critical to the stability of the original bank material in that it aids in preventing scour or sloughing. Prior to selecting a filter type, the hydraulic designer should first consult with the Region Materials Engineer and the RHE to determine if there is a preference. In areas of highly erodible soil (fine, clay-like soils), the State Hydraulics Office should be consulted, and an additional layer of sand may be required. For additional guidance selecting the appropriate filter material, see HEC-23, Volume 1 and Volume 2. Use of the FHWA Hydraulic Toolbox is required for design of filters.

The thickness of rock placed (Figure 4-8) depends on which type of rock was selected: quarry spalls or RESP Class A, B, or C. Additional guidance for determining minimum rock thickness can be found in HEC-23, Volume 1 and Volume 2. Care should be taken during construction to ensure that the range of rock sizes, within each group, is evenly distributed to keep the rock stable. Rock is required to be extended to 1 foot above the scour design flood water surface elevation as shown in Figure 4-8. However, if severe wave action is anticipated, it should extend farther up the bank.

The hydraulic designer and construction inspectors must recognize the importance of a proper toe or key at the bottom of any rock bank protection. The toe of the rock is placed below the channel bed to a depth equaling total scour at the scour check flood (Figure 4-8). If the estimated scour is minimal, the toe is placed at a depth equivalent to the thickness of the rock to help prevent undermining. Without a toe, the rock has no foundation and the installation is certain to fail. Added care should be taken on the outside of curves or sharp bends where scour is particularly severe. The toe of the bank protection may need to be placed deeper than in straight reaches.