Various methods of damp proofing are as given below:

1. Providing D.P.C. course

2. Providing cavity walls

3. Surface treatment

4. Integral treatment

5. Guniting and

6. Pressure grouting.

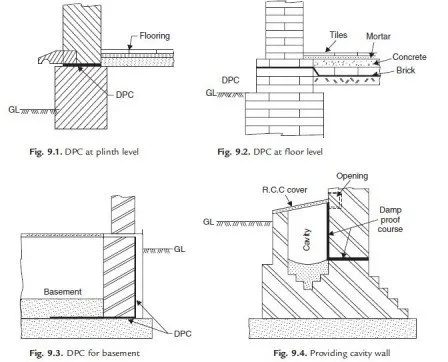

1. Providing damp proof course: It consists of providing a damp proof course between the source of dampness and building component. The DPC may be with any water repellant material like bitumen, mastic asphalt, cement concrete, metal or plastic sheets. DPC should cover full width of wall. It should be laid on levelled surface of mortar. Joints should be minimum and should not be at critical points. When horizontal DPC on roof is continued on vertical face of parapet wall, the junction should be filled with about 75 mm fillet of cement concrete. Figure 9.1 shows details of providing water proof course at plinth level. Whereas Figure 9.2 shows the details of water proofing course for wall and floor. Figure 9.3 shows details of water proofing course for basement.

2. Providing cavity wall: Cavity wall may be constructed to protect foundation masonry and the wall as shown in Fig. 9.4. The cavity prevents moisture travelling from outer to inner wall.

3. Surface treatment: If moisture is only superficial and not under pressure this method is useful. It consists of application of layer of water repellant compounds on the surface. Some of the water proofing agents used for such treatment are silicates of sodium or potassium and sulphates of aluminium, zinc and magnesium.

4. Integral treatment: It consists in mixing commercially available compounds in water before concrete is wet mixed. These compounds are made from chalk, talc, flutter earth or chemical compounds like calcium chloride, aluminium sulphate, calcium chloride etc. Some compounds contain compounds like soap, petroleum oils, fatty acids etc.

5. Guniting: In this method a mixture of cement and water is forced by cement gun on the surface to be made water proof. Later 1 : 3 or 1 : 4 cement mortar is applied to the surface with pressure using compressed air. Thus an impervious layer of mortar is provided.

6. Pressure grouting: This is the method used to seal cracks in the concrete surfaces. In this method cement grout is forced under pressure.

Site is very informative…..