The J-ring test (EFNARC 2002; Bartos, Sonebi, and Tamimi 2002) extends common filling ability test methods to also characterize passing ability.

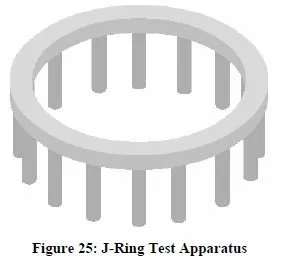

The J-ring test device can be used with the slump flow test, the orimet test, or the V-funnel test. The J-ring, as shown in Figure 25, is a rectangular section (30 mm by 25 mm) open steel ring with a 300 mm diameter. Vertical holes drilled in the ring allow standard reinforcing bars to be attached to the ring. Each reinforcing bar is 100 mm long. The spacing of the bars is adjustable, although 3 times the maximum aggregate size is typically recommended. For fiber-reinforced concrete, the bars should be placed 1 to 3 times the maximum fiber length.

To conduct the J-ring test in conjunction with the slump flow test, the slump cone is placed in the center of the J-ring and filled with concrete. The slump cone is lifted and concrete is allowed to spread horizontally through the gaps between the bars. Alternatively, the orimet device or the Vfunnel can be positioned above center of the J-ring. Instead of measuring just the time for concrete to exit the orimet or the V-funnel, the concrete is also allowed to spread horizontally through the J-ring.

Various interpretations of the test results have been suggested. The measures of passing ability and filling ability are not independent. To characterize filling ability and passing ability, the horizontal spread of the concrete sample is measured after the concrete passes through the gaps in the bars of the J-ring and comes to rest. Also, the difference in height of the concrete just inside the bars and just outside the bars is measured at four locations. The smaller this difference in heights is, the greater the passing ability of the concrete will be. Alternatively, the horizontal spread with and without the J-ring can be compared as a measure of passing ability.