The delivery-chute torque meter (US patent 4,332,158; Wong et al. 2000) is designed to measure the consistency of concrete as it exits a concrete mixing truck. The intent of the device is to measure slump accurately without having to wait for the conventional slump test to be performed.

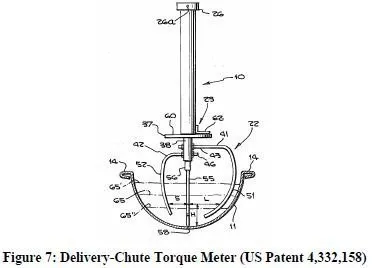

The hand-held device, which is shown in Figure 7, is inserted in flowing concrete in the delivery chute of a concrete mixing truck. The two curved sensing blades are attached to a vertical member that measures torque. The device is inserted in the delivery chute such that the sensing blades are orthogonal to the flow of concrete. The flowing concrete applies approximately equivalent forces to each of the two sensing blades. These forces create opposing moments on the inner vertical member. Since the length of the moment arm for the right sensing blade is approximately twice that of the moment arm for the left sensing blade, a net torque is applied to the inner vertical member. The operator manually applies an opposing torque to the outer housing to keep the blades orthogonal to the flow of concrete. The magnitude of this applied torque is indicated on the flat circular plate located just above the two sensing blades. The torque measured with the device is correlated to slump, with the appropriate correlation marked on the circular plate. For concretes with different viscosities, different calibrations must beobtained. The geometry of the device allows the device to adjust automatically to changes in flow velocity and height.

Advantages:

The device measures the workability of the concrete as it exits the mixer before it is

placed.

The torque (and associated slump) is read directly from the device. No computer or other sensing devices are required to determine slump.

Disadvantages:

The torque meter is a single-point test that gives no indication of plastic viscosity.

Readings are made at only one shear rate.

The device must be calibrated for each concrete mixture.