The delivery-chute depth meter (US patent 4,578,989; Wong et al. 2000) is similar to the delivery-chute torque meter in that it measures the consistency of concrete as it exits a concrete

mixing truck.

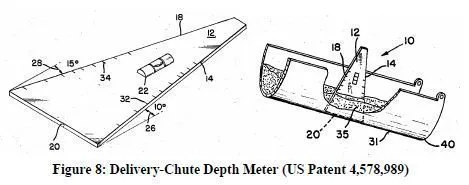

The device is a triangular plate with an attached level, as shown in Figure 8. The angles at the base of the triangular plate are used along with the attached level to set the discharge chute to predefined angles. Concrete is allowed to flow down the discharge chute until it begins to fall off the end of the discharge chute. At that point, concrete flow is stopped and the device is inserted into the concrete. The height of the concrete in the chute, as measured on the triangular plate, is related to slump.

The device must be calibrated for each concrete mixture tested. For a given concrete mix, the water content is systematically altered. For each water content, the slump and the depth of flow in the delivery chute are recorded in order to develop points on the device. Given that eachseparate concrete mixture must be calibrated separately, the device is best suited for jobs where a large quantity of one concrete mixture is being placed.

Advantages:

The device allows workability to be judged quickly before any concrete exits the end of the delivery chute.

The device is simple and inexpensive.

Disadvantages:

The device must be calibrated for each concrete mixture.

Any variations in concrete height along the length of the delivery chute could distort readings.