The Tattersall two-point device (Tattersall and Bloomer 1979; Cabrera and Hopkins 1984; Tattersall 1990; Tattersall 1991; Ferraris and Brower 2001; Bartos, Sonebi, and Tamimi 2002) was one of the earliest attempts to measure the rheology of concrete based on the Bingham model and one of the first devices to use impeller geometry. The device has been refined over the years by Tattersall and other researchers (Wallevik and Gjorv 1990) and continues to be widely used in research.

The two-point device was originally developed by G. H. Tattersall at Sheffield University in the 1970s. Tattersall determined that coaxial cylinders rheometers would be inappropriate for measuring concrete because of the formation of a failure plane in the concrete between the cylinders. Instead, Tattersall decided to measure the torque required to turn an impeller in concrete. The development of the device began by using an ordinary food mixer fitted with a stirring hook and connected to a dynamometer wattmeter, which measured torque. This initial device was referred to as the MK I. In contrast to a coaxial cylinders rheometer, the hook of the MK I constantly came in contact with new concrete (Tattersall and Banfill 1983).

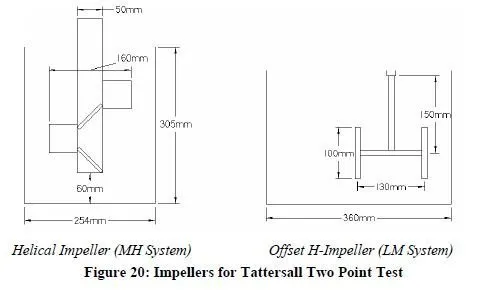

To extend the range of the initial food mixer device, a more sophisticated, specialized device was developed. This device, initially known as the MK II, is the device now commonly referred to as the Tattersall two-point device. The device consists of a stationary bowl mounted in a large frame. A hydraulic drive unit motor turns an impeller that is immersed in the concrete sample. Two different impellers are available for use based on the workability of the concrete. The MH system, which is used for slumps greater than 75-100 mm, consists of four angled blades in a helical pattern on a central shaft. The blades provide mixing action by essentially lifting the concrete. Alternatively, the LM system is intended for lower workability mixes with slumps less than 50 mm. It consists of an offset H-shaped blade that moves in a planetary motion in the concrete. When the H-shaped impeller is installed for use in a planetary motion, the device is sometimes referred to as the MK III. In addition to low slump concretes, the LM system better measures self-compacting concrete and certain high performance concretes with high plastic viscosity because this higher plastic viscosity reduces the efficiency of the mixing of the MH system. The MH and LM impeller systems are depicted in Figure 20.

In early versions of the device, the speed of the impeller was manually controlled and the torque was measured by monitoring the oil pressure in the hydraulic drive unit motor, as read from a pressure gauge. Later versions of a device use a tachometer and pressure transducer to allow continuous recording of data. The device has also been modified by adding a vibrator to characterize the effects of vibration on concrete rheology (Tattersall and Baker 1988).

The output of the device, shown in Equation [10], is given in terms of g and h which are related to yield stress and plastic viscosity, respectively. The device must be calibrated in order to determine yield stress and plastic viscosity in fundamental units. The calibration is performed using a Newtonian fluid of known viscosity and a power law fluid with a known flow curve.

T = g + hN

where T = torque and N = rotation speed.

Although it was intended for use in the lab and on site (Tattersall 1991), the device has been used

predominately in laboratory research.

Advantages:

The device measures both plastic viscosity and yield stress.

The device has been used widely in research, particularly when compared to other rheometers.

The choice of two impellers allows the measurement of a wide range of concrete mixtures, from 2 inch slump concrete up to self-compacting concrete.

The device can be used to measure the effects of vibration on concrete rheology.

Disadvantages:

The test device, in its current form, is larger and bulkier than some other rheometers, particularly the BTRHEOM rheometer. The devices size limits its use in the field.

The device must be calibrated.

Over long periods of time, the device can cause segregation in concrete mixtures, even when segregation would not be a problem in the field.