The turning tube viscometer (Hopkins and Cabrera 1985; Ferraris 1999) is based on the same principle as the moving sphere viscometer namely, Stokes Law but is only considered appropriate for testing mortar.

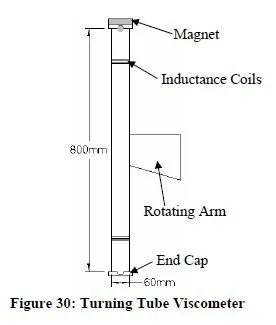

An 800 mm long, 60 mm diameter tube is attached to a rotating arm, which allows the tube to be rotated in the vertical plane. A metal ball is allowed to fall through the fresh mortar in the tube.

A magnet can be placed on the specially milled end caps to ensure that the ball starts in the center of the tube. Inductance coils wrapped around the tube at two locations detect when the ball passes in order to determine the time for the ball to fall a known distance.

The test is conducted with different ball diameters and the results of the test are plotted on a graph of the inverse of the ball diameter squared versus time. The apparent viscosity of the concrete can be calculated based on Stokes law. Since the assumption in Stokes law that the ball is moving slowly through a fluid of infinite size is not valid for the test apparatus, correction factors are applied to provide a more accurate result.

The dimensions of the device are not large enough to permit the turning tube viscometer to be used for concrete. The ball diameter should be significantly greater than the maximum aggregate size so that the fluid can be considered a uniform medium. Further, the diameter of the tube should be sufficiently large to avoid interlocking of aggregate particles, which could interfere with the balls descent.