Masonry means construction of buildings using building blocks like stone, bricks, concrete blocks etc.

Masonry is used for the construction of foundation, plinth, walls and columns. Mortar is the binding material for the building blocks. In this article different types of stone masonry used are explained and points to be observed while supervising stone masonry works are listed.

Types of Stone Masonry

Mainly there are two types of stone masonry:

1. Rubble Masonry

2. Ashlar Masonry

1. Rubble Masonry: In this type of constructions stones of irregular sizes and shapes are used.

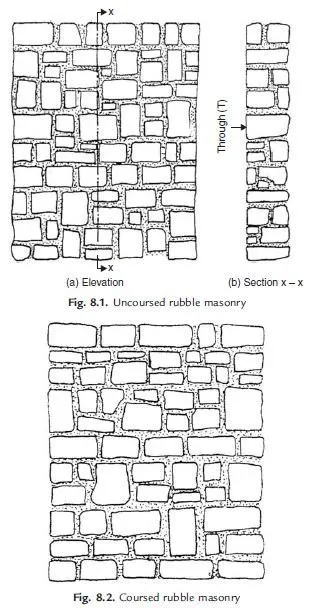

To remove sharp shapes they may be hammered. The rubble masonry may be coursed or uncoursed [Fig. 8.1 and 8.2]. In uncoursed rubble masonry the wall is brought to level at every 300 mm to 500 mm. The mortar consumed in these construction is more. Course rubble masonry is used for the construction of public and residential buildings. Uncoursed rubble masonry is used for the construction of foundations, compound walls, garages, labour quarters etc. A skilled mason may arrange the facing stones in polygonal shapes to improve the aesthetic of the wall.

Ashlar Masonry

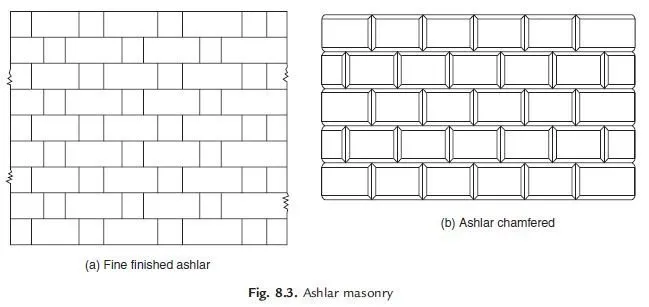

In this type of masonry stones are dressed to get suitable shapes and sizes. The height of the stones varies from 250 mm to 300 mm. The length should not exceed three times the height. The dressing of the stone need not be very accurate on all sides. Usually good dressing is made on facing side. In such construction mortar consumption is less compared to rubble masonry.

There are different types of ashlar masonry depending upon the type of dressing such as Ashlar fine dressed, Ashlar rough dressed, Ashlar rock or quarry faced, Ashlar facing, Ashlar chamfered etc. Figure 8.3 show some of such masonry.

Supervision of Stone Masonry Construction

The following points should be kept in mind in supervising stone masonry work:

1. Hard and durable stones, free from defects like flaws, cavities veins etc. should be used.

2. Dressing of the stones should be as per the requirement.

3. Stones should be properly wetted before they are used so as to avoid sucking of water from mortar.

4. Stones should be laid on their natural bed.

5. Facing and backing faces should be laid neatly and levelled and checked with wooden template.

6. The heart of masonry should be filled with stone chips and mortars. To thick mortar joints should be avoided.

7. Verticality of the wall should be frequently checked with plumb-bob.

8. Mortars with correct proportion of sand and cement should be used.

9. Continuous vertical joints should be avoided.

10. Through stones should be used within 1.5 m distances.

11. The height of masonry should be raised uniformly.

12. Under the beams, trusses, sills etc large flat stones should be used.

13. Before continuing work, the masonry built on previous day should be well cleaned and freed from loose particles.

14. Curing should be done properly for 2 to 3 weeks.

sir we need more details